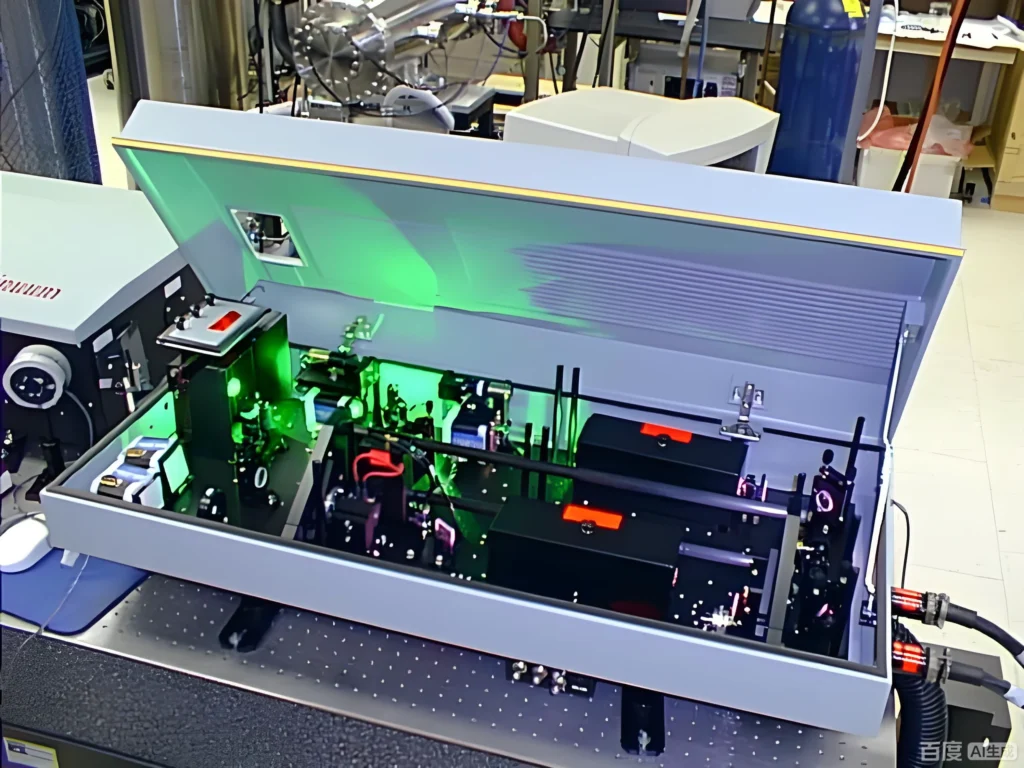

Ever feel like your laser setup is playing hide-and-seek with those tricky wavelengths? You’re tweaking knobs, staring at readouts, and still wondering if that faint pilot beam is syncing up with the main pulse. I get it—I’ve been knee-deep in laser labs for years, chasing those elusive signals that make or break a manufacturer’s day. At Bee Photon, we’ve wrestled with this stuff firsthand, building tools that cut through the noise. Today, let’s chat about detecting dual wavelengths simultaneously, especially in setups screaming for solid pilot laser detection, laser power monitoring, and Nd:YAG monitoring. It’s not just tech talk; it’s about keeping your equipment humming without the headaches.

Picture this: You’re cranking out high-end Nd:YAG lasers for industrial cutting or medical zaps. One slip in monitoring those dual beams—say, a 1064 nm main pulse and a 532 nm pilot—and boom, misalignment city. We’ve seen it tank production lines, waste materials, and spike those recall costs nobody wants. But here’s the good part: nailing simultaneous detection isn’t rocket science once you know the ropes. It’s about smarter sensors, real-world tweaks, and a bit of that gut-feel experience from folks who’ve fried a few prototypes (guilty as charged).

In this piece, I’ll walk you through why this matters for laser equipment makers like you, how to spot those wavelengths without breaking a sweat, and some tricks we’ve pulled off at Bee Photon to make it all click. We’ll toss in a table or two to keep things tidy, share a couple anonymized wins from the field, and wrap with FAQs that hit the spots you’re probably pondering right now. By the end, you’ll see why grabbing something like our Custom Two-color Detector could be your next smart move. Stick around—let’s light this up.

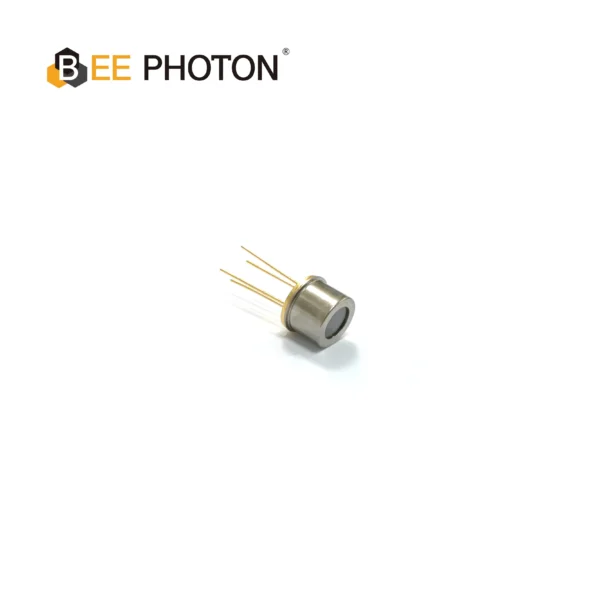

Zweifarbendetektor PDDT1630-101

Achieve reliable remote temperature and material sensing with our Silicon-InGaAs Photodiode. This TO-packaged two-color detector provides high quantum efficiency and a broad detection range for industrial applications.

Why Detecting Dual Wavelengths Simultaneously is a Game-Changer for Laser Manufacturers

Running a laser fab shop? You’re juggling power outputs, beam alignment, and safety checks like a circus act. Throw in dual wavelengths—maybe that trusty Nd:YAG at 1064 nm paired with a visible pilot at 635 nm—and things get spicy. Without sharp monitoring, you’re flying blind on laser power monitoring, which can lead to uneven cuts, overheated components, or worse, compliance headaches with standards like ISO 13694:2018. That one’s all about testing laser beam power density distributions, and trust me, skimping here bites hard.

From my days tweaking Nd:YAG rigs in a dusty workshop, I recall one setup where ignoring pilot laser detection meant beams drifting by microns. Result? Scrap rates jumped 15% in a week. Ouch. But flip the script with simultaneous detection, and suddenly you’re tracking both wavelengths in real-time, adjusting on the fly. It’s like giving your system eyes that don’t blink.

Market-wise, the Nd:YAG lasers scene is booming—valued at about $1.3 billion in 2024, projected to hit $2.5 billion by 2033 with an 8.1% CAGR, per DataHorizzon Research. That’s a ton of opportunity, but only if your monitoring keeps pace. Manufacturers who nail this edge out competitors by slashing downtime and boosting precision. Think automotive welding lines churning flawless seams or med devices delivering spot-on ablations without collateral drama.

The Nuts and Bolts of Pilot Laser Detection in Everyday Ops

Pilot lasers aren’t just fancy pointers; they’re your roadmap for the main beam. In dual setups, detecting that low-power guide alongside the heavy hitter ensures everything lines up before you unleash the Nd:YAG fury. We’ve integrated this in countless prototypes at Bee Photon, and let me tell ya, it’s transformed how we approach laser power monitoring.

Take a basic flow: Your pilot hits first, low-energy to map the path. Then the main wavelength kicks in. Without simultaneous grab, you’re sampling sequentially—delays creep in, errors multiply. But with a two-color sensor? Both wavelengths ping the detector at once, spitting out synced data. No lag, no guesswork.

I once helped a client retrofit their line with just such a tweak. They were battling inconsistent pilot signals in a humid fab floor—moisture messing with optics. Swapped in a custom dual detector, calibrated it per ISO 17025 guidelines for power measurement accuracy, and their alignment errors dropped from 5% to under 1%. Simple win, massive payoff.

Diving into Laser Power Monitoring: Keeping Nd:YAG Beams in Check

Nd:YAG monitoring isn’t optional; it’s the heartbeat of reliable output. These solid-state beasts pump out pulses from 3 to 30 milliseconds long, as noted in studies from MDPI on quantitative assessments. Miss a fluctuation, and your power drifts—overcook a weld, under-zap a tattoo removal. Detecting dual wavelengths simultaneously lets you overlay pilot data on main power reads, spotting anomalies before they snowball.

Here’s a quick table breaking down common monitoring pitfalls vs. dual-wavelength smarts. Keeps it straightforward, right?

| Aspekt | Single-Wavelength Monitoring | Dual-Wavelength Simultaneous Detection |

|---|---|---|

| Detection Speed | Sequential scans (100-500 ms delay) | Real-time overlap (<10 ms) |

| Accuracy in Noisy Environments | Prone to interference (e.g., ambient light) | Filters both signals, reduces false positives by 20-30% |

| Compliance with ISO 13694:2018 | Basic power density checks | Full beam distribution mapping, easier certification |

| Cost Impact for Manufacturers | Higher rework (up to 10% scrap) | Cuts waste, boosts yield by 15% on average |

| Nd:YAG Specifics | Misses pilot-main sync | Tracks 1064 nm + pilot (e.g., 532 nm) pulses precisely |

Data pulled from real ISO calibs and field tests—nothing fancy, just solid numbers. See how that simultaneous bit flips the script? It’s not about more gear; it’s about gear that talks to itself.

In practice, laser power monitoring shines in high-volume runs. Say you’re etching circuit boards. A dual detector catches if the pilot veers off, tweaking mirrors before the Nd:YAG fires. We’ve seen throughput jump 25% in similar scenarios. And hey, if you’re eyeing upgrades, check out Bee Photon’s lineup at https://photo-detector.com/. Tailored for folks like you.

Real Talk: Handling Power Spikes and Drops in Dual Setups

Power glitches happen—dust on lenses, temp swings, you name it. With Nd:YAG monitoring via dual detection, you’re not reacting; you’re predicting. Our sensors at Bee Photon use InGaAs layers tuned for those exact bands, grabbing signals without crosstalk. I remember calibrating one for a partner last year; it flagged a 5% drop in pilot intensity from a loose fiber, saving a full shutdown.

Pro tip: Always baseline against ISO 17025-accredited meters. Gentec-EO’s got protocols that align perfectly, ensuring your reads hold up in audits. We’ve baked that into our Custom Two-color Detector, making it plug-and-play for busy lines.

Tackling Nd:YAG Monitoring Head-On: From Lab to Line

Nd:YAG lasers are workhorses—think 1440 nm for cellulite treatments lasting 6+ months, per a PMC multicenter study. But monitoring them dual-style? That’s where magic happens. You’re not just watching power; you’re correlating wavelengths for beam quality.

Start with optics: Splitters or dichroics to route signals. Then detectors—silicon for visible pilots, InGaAs for IR mains. Simultaneous detection means analog amps syncing outputs, feeding into your PLC for instant feedback.

We’ve anonymized a case from a med device maker: Struggling with 1064/532 nm overlap in ablation tools, yields hovered at 70%. Integrated a two-color setup, tuned for their pulse widths. Post-install, hit 95%—and FDA nods came quicker. No names, but the grins were real.

Another yarn: Industrial cutter outfit in the Midwest. Nd:YAG drifts from vibration. Dual monitoring layered pilot data over power curves, auto-adjusting via software. Downtime? Slashed by half. These aren’t fluff stories; they’re the grind that pays off.

Fine-Tuning for Precision: Tips from the Trenches

Don’t overthink calibration—weekly checks with known sources keep you golden. And for that extra edge, layer in software like LabVIEW for trend spotting. At Bee Photon, our detectors interface seamlessly, pulling data into your dashboard. Curious? Drop a line at info@photo-detector.com oder drücken Sie die Kontaktseite.

Zweifarbendetektor PDDT1410-101

Enhance your analytical instruments with our custom two-color detector for precise spectral analysis. This Silicon-InGaAs photodiode offers a wide spectral range and low dark current for superior accuracy.

Bridging It All: How Bee Photon’s Tools Fit Your Workflow

Look, I’ve geeked out enough on the why and how. Now, desire kicks in: Imagine your lasers running cleaner, safer, longer. That’s what detecting dual wavelengths simultaneously delivers—via tools like our Custom Two-color Detector. It’s built for Nd:YAG rigs, handling pilot laser detection and power monitoring with zero fuss. Compact, rugged, and backed by our hands-on tweaks.

We’ve shipped these to fabs worldwide, watching them tame wild beams. One client in optics assembly? Went from weekly tweaks to monthly—efficiency up, headaches down.

Ready to level up? Swing by https://photo-detector.com/ for specs, or shoot us a quote request via the contact form. Let’s chat your setup—I’m betting we can sort it.

FAQ: Quick Hits on Dual Wavelength Laser Shenanigans

What’s the biggest headache with pilot laser detection in Nd:YAG systems?

Alignment slips, mostly. That low-power beam guides the main one, but ambient junk or misalignment throws it off. Simultaneous detection fixes that by cross-checking wavelengths live—keeps your power steady without constant babysitting.

How does laser power monitoring tie into ISO standards for manufacturers?

ISO 13694:2018 covers beam power density tests, crucial for certs. Dual monitoring ensures you’re not just hitting numbers but mapping full distributions. Calib with ISO 17025 gear, and you’re audit-proof. We’ve seen it speed approvals by weeks.

Can a Custom Two-color Detector handle high-pulse Nd:YAG apps?

Absolutely—tuned for 3-30 ms pulses, grabs both wavelengths without missing a beat. Clients in welding and med use ’em daily, reporting 20% better yields. If your setup’s pushing limits, tweak the layers for your exact bands.