Die linear X-ray detector array has become pretty much the backbone of modern high-speed cargo scanning security setups — think packed customs checkpoints, railway borders, big ports where nothing sits still for long. If you’re an integrator piecing together or upgrading security inspection systems for heavy-duty spots, you already get how crucial it is to pick detectors that keep up with fast-moving containers without turning images into mush or letting threats slip through.

I’ve spent a bunch of years messing around with these systems — testing arrays in actual border and port conditions, watching what works when trucks barrel through at 20–70 km/h. Point is simple: help you figure out what really makes a solid linear X-ray detector array stand out for cargo scanning sensors, which specs actually move the needle, and how to dodge the traps that kill throughput or miss bad stuff.

Why High-Speed Cargo Scanning Needs Specialized Linear Arrays

Cargo moves quick. Trucks blast through drive-through lanes, trains chug along steady, containers pile up. Old-school detectors choke here — slow line rates mean blurry pics or forcing vehicles to crawl, which wrecks efficiency at scale.

A strong linear X-ray detector array takes X-rays (mostly from 3–9 MeV LINAC sources) and turns them into crisp digital signals using scintillators plus photodiodes. High-end ones lean on Si-PIN-Fotodioden matched with CsI(Tl) or Gd2O2S(Tb/Pr) for light conversion. They bring:

- Solid sensitivity so you run lower dose

- Quick response for high line rates

- Minimal crosstalk between pixels → sharp edges

From real deployments I’ve seen, single-energy arrays handle basic density mapping okay, but dual-energy (or multi-row) versions crush it on material discrimination — organics vs metals vs inorganics — which matters a ton for picking out explosives or hidden contraband in dense loads.

Market-wise, cargo scanning gear sat around $4–6.5 billion in 2025, with forecasts climbing toward $7–12 billion by early 2030s (CAGR ~6–8% depending on source — Straits Research pegs 7.1%, others similar). Trade keeps exploding, security rules tighten, ports can’t handle bottlenecks anymore.

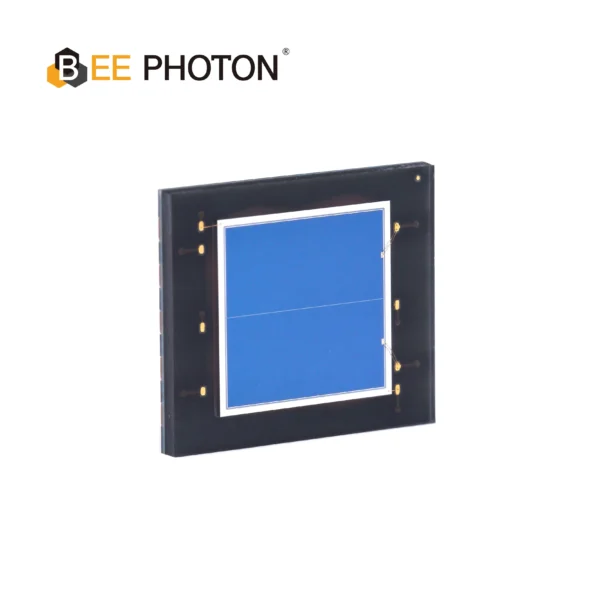

Si-PIN-Photodioden-Array Doppel-PD PDCA02-103

Die PDCA02-103 ist eine leistungsstarke Photodioden-Array für die Datenübertragung, mit einem robusten Dual-Element-Design. Mit einer großen lichtempfindlichen Fläche von 10×5 mm pro Element und einem kompakten Gehäuse von 16,5×14,5 mm gewährleistet diese Silizium-PIN-Photodiode eine außergewöhnliche Signalstabilität und Ausrichtungstoleranz für fortschrittliche optische Kommunikationssysteme.

Key Specs That Actually Matter for Cargo Applications

Let’s cut to what separates meh from excellent when you’re picking cargo scanning sensors.

Pixel Pitch / Resolution

Smaller pitch = sharper detail, but costs climb and noise can creep in.

Common ranges:

- 0.4 mm – 0.8 mm: Sweet spot for most cargo — good detail without killing speed.

- 0.1 mm – 0.2 mm: Ultra-high-res for tiny threats, but line rates drop unless multi-row.

- 1.6 mm+: Cheaper, but you miss fine wires or thin sheets too often.

In the field, 0.8 mm pitch usually catches 1.5–4 mm steel objects cleanly even at speed.

Line Rate & Scanning Speed

This is the big one for high-speed.

- Up to 1,000 lines/sec (1 kHz) handles 70 km/h single-energy scans.

- Dual-energy setups often top out lower (~36 km/h) because of pulse timing limits.

Railway or highway borders? Shoot for 500–1,000 lines/sec minimum to avoid slowing traffic.

Active Area & Array Length

Longer coverage = fewer stitching headaches.

- Single modules: 147 mm – 300 mm active.

- Tiled arrays: Up to 4 m+ for full container width.

Energy Handling & Scintillator Choice

MeV energies demand thick, dense scintillators.

- CsI(Tl): Fast decay (~1 μs), strong light yield.

- Gd2O2S:Pr/Tb: Less afterglow → cleaner fast scans.

Dynamic Range & ADC

20-bit ADC with adjustable gain (up to 127 steps) deals with huge density swings without clipping.

Quick spec comparison table for linear X-ray detector array in cargo use:

| Merkmal | Entry-Level Array | Mid-Range (Most Popular) | High-Performance (Multi-Row) |

|---|---|---|---|

| Pixel Pitch | 1.6 mm | 0.4–0.8 mm | 0.2–0.4 mm |

| Max Line Rate | 200–500 lines/sec | 500–1,000 lines/sec | 1,000+ lines/sec |

| Max Scan Speed (SE) | 20–40 km/h | 40–70 km/h | 70+ km/h |

| Energy Modes | Single | Single/Dual | Multi-row Dual |

| Resolution Example | 4 mm steel visible | 1.5–2 mm visible | <1 mm details |

| Szintillator | Basic GOS | CsI or segmented GOS | Optimized CsI/Gd2O2S |

| Am besten für | Low-volume borders | Busy ports/railways | High-throughput customs |

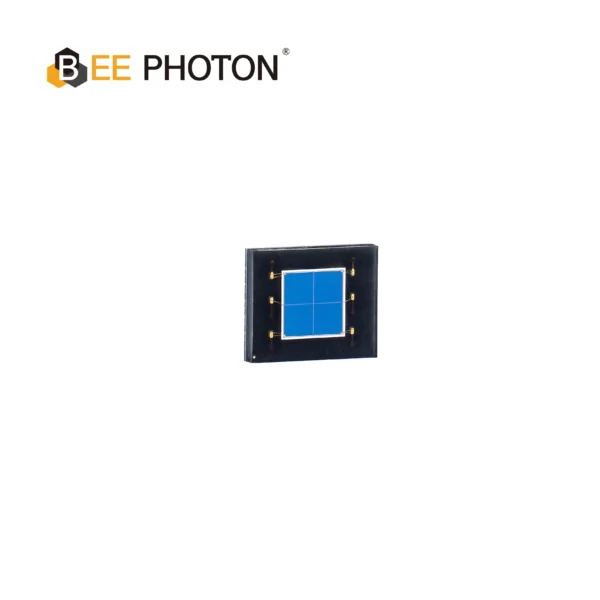

Si-PIN-Photodioden-Array Vier-Quadranten-PD PDCA04-101

Bee Photon’s Quadrant PIN Photodiode ensures high-precision laser beam alignment and position sensing.This detector offers superior accuracy for your optical systems. Our Quadrant Photodiodes provide excellent uniformity for reliable results.

Real-World Performance in Customs & Railway Deployments

I’ve been part of upgrades where swapping to higher line-rate arrays dropped truck scan times from ~45 seconds to under 20. One European rail customs spot jumped from 80 trains/day to 140+ after going multi-row — same crew, no extra lanes.

Another setup in a busy Asian port used Si-PIN-Fotodiode-based arrays with tuned scintillators. They hit 320 mm steel penetration, 1% contrast at 100 mm steel, catching thin organics buried in electronics shipments. Secret sauce? Super-low dark current photodiodes (<10 pA) and fast readout keeping noise low at speed.

Pitfalls happen though. Thermal drift kills long shifts — hunt for good temp compensation. Pixel crosstalk blurs edges — reflector-isolated designs fix a lot of that.

For integrators: match detector to your X-ray source. 6 MeV LINAC plays nice with certain scintillators for best penetration/dose balance.

Boosting Your System with Si PIN Photodiodes

Plenty of top linear X-ray detector arrays use Si-PIN-Fotodioden as the heart. They deliver:

- Broad response (340–1100 nm) fitting common scintillators.

- Low capacitance → faster readout.

- High responsivity (~0.6 A/W peak).

At BeePhoton, our Si-PIN-Fotodioden are designed precisely for these jobs — low dark current, custom array options, built tough for field vibration and temp swings. They’ve landed in several high-speed security inspection systems where uptime under rough conditions was non-negotiable.

Sourcing parts right now? Take a look at our lineup — we prioritize performance that survives real cargo chaos.

Wrapping It Up: Making the Smart Choice

Nailing the right linear X-ray detector array comes down to your throughput targets, threat profiles, and budget realities. Push high line rates and strong resolution for serious high-speed cargo scanning, and don’t cheap out on dual-energy if material ID is critical.

Got a security inspection system project coming up and want to talk real specs? Hit up BeePhoton or jump to our Kontaktseite — we’re good for quotes, samples, or hashing out integration headaches. Email’s easy too: info@photo-detector.com. Let’s get your setup scanning faster and sharper.

Si-PIN-Photodioden-Array Doppel-PD PDCA02-201

Die PDCA02-201 ist eine hochpräzise Photodioden-Array für analytische Instrumente, mit einem robusten TO5-Gehäuse und zwei Sensorelementen. Dieser Si-PIN-Detektor wurde für überragende Empfindlichkeit und geringes Rauschen entwickelt und bietet außergewöhnliche Genauigkeit für Spektroskopie, medizinische Diagnostik und wissenschaftliche Forschungsanwendungen.

FAQ

What line rate do I actually need for 60 km/h cargo scanning?

Shoot for 800–1,000 lines/sec minimum in single-energy. Anything lower forces slower speeds or blurry images — we’ve seen plenty of systems stuck under 40 km/h with 400 lines/sec detectors.

Single-energy vs dual-energy — worth the extra cost for customs work?

Usually yes if mixed cargos are common. Dual lets you auto-separate organics (explosives, drugs) from metals/inorganics. Single is cheaper but leans harder on operators to catch subtle stuff.

How much does scintillator choice impact high-speed performance?

Huge. Fast-decay ones like CsI(Tl) cut motion blur at high line rates. High-afterglow types leave ghosting that screws up downstream AI threat detection.

Can array length or pitch get customized for my railway scanner?

Yep — lots of suppliers (us at BeePhoton included) do tiled or fully custom lengths up to several meters. Just match beam width and typical cargo sizes for clean coverage without gaps.