Designing something that needs to watch dozens, hundreds, or even thousands of light signals all at the exact same moment is brutal. I’ve been on the bench when a customer shows up with a breadboard full of discrete photodiodes, miles of coax cable, and a face that says “this isn’t working.” Nine times out of ten, the fix is ripping all that out and dropping in a proper photodiode array.

First, Let’s Clear Up What a Photodiode Array Actually Is

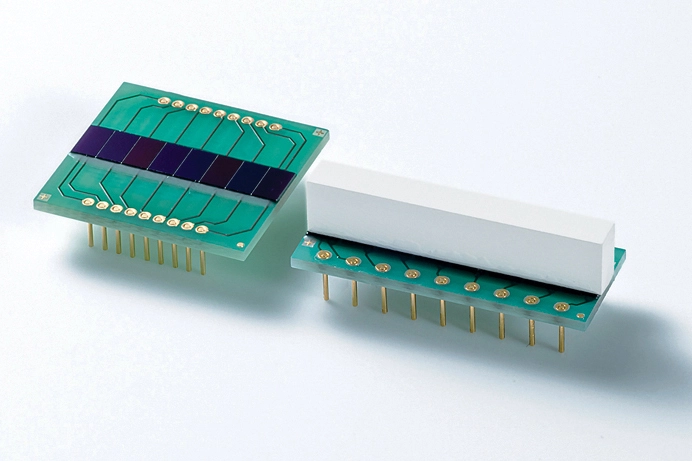

Think of it as a ruler made of light detectors. Instead of one photodiode sitting alone in a TO-can, you get 16, 64, 256, 512, 1024 (or even more) tiny photodiodes fabricated side-by-side on the same piece of silicon, wired out to a nice orderly row or grid of pins. They all see almost exactly the same temperature, they’re matched to within a couple percent right out of the wafer, and you only have one package to cool or mount instead of a whole Christmas tree of parts.

At Bee Photon the workhorse is our B2B Si-PIN-Photodioden-Array family. Typical specs that make designers happy:

- Pixel size 25 µm × 500 µm up to 100 µm × 100 µm (you pick)

- Dark current usually 0.2–1 pA per pixel at 25 °C

- Shunt resistance > 1 GΩ

- Responsivity 0.6 A/W at 900 nm with proper AR coating

- Crosstalk < 0.05 % between neighboring pixels

We keep hundreds of standard variants in stock, but 60 % of orders still end up with at least one small customization — different pitch, scintillator coating, built-in TEC, whatever you actually need.

Si-PIN-Photodioden-Array Vier-Quadranten-PD PDCA04-102

Finden Sie Ihr B2B Si PIN Photodioden-Array bei Bee Photon, einem zuverlässigen Hersteller für OEM-Kunden. Unsere Vier-Quadranten-Detektoren bieten eine hohe Konsistenz für industrielle Anwendungen und Großaufträge. Kontaktieren Sie uns für Ihren Bedarf an kundenspezifischen Photodioden-Arrays.

Why Discrete Detectors Fall Apart When You Go Multi-Channel

Let me paint you a picture. A startup came to us in 2023 building a 1024-channel fluorescence correlation spectroscopy setup. They started with individual Hamamatsu S13360 MPPC modules — great parts, don’t get me wrong. But once they glued 1024 of them to a PCB the gain variation was ±18 %, temperature drift was different on every corner of the board, and the whole thing drew 28 watts just for bias. They burned eight months and most of their seed round.

We swapped them to two 512-pixel linear photodiode arrays plus a simple 32-channel TIA ASIC each. Power dropped to 1.8 W, channel-to-channel variation fell to ±1.7 %, and they shipped their first beta units three months later. That’s the kind of time-to-market swing a good photodiode array gives you.

How Photodiode Arrays Completely Changed Spectroscopy

Old-school scanning monochromators are like watching Netflix with a 56k modem — you get the picture, but frame by frame and painfully slow. A photodiode array is fiber-optic broadband: every wavelength lands on its own pixel and you read the entire spectrum in one shot.

Real customer data from a food-safety lab doing NIR transmission on flowing grain (2024):

| Metric | Old Scanning System (single InGaAs detector) | New Fixed-Grating + 512-pixel PDA System |

|---|---|---|

| Full spectrum time | 120 ms | 80 µs |

| Throughput (samples/hour) | ~800 | >12,000 |

| Detection limit for protein | 0.18 % | 0.09 % |

| Yearly maintenance cost | $9,800 | $1,200 |

They paid for the new detector in under five weeks just on increased sample volume.

Another favorite story — a pharmaceutical company measuring tablet dissolution in real time. The reaction kinetics they cared about happened in <400 ms windows. Scanning system completely missed the curve. Switched to our cooled 1024-pixel linear array and suddenly they could resolve 8 ms steps. Regulatory loved the data repeatability, product got approved six months earlier than planned.

Imaging Side: Hyperspectral, Medical, Machine Vision

In hyperspectral push-broom imaging you fly or move the scene past a slit and the spectrometer spreads each line across the array. Uniformity across the photodiode array is everything — one pixel 5 % brighter than its neighbor and your vegetation index map looks like a zebra.

One drone company we work with maps 400 hectares of vineyard per day at 3 cm/pixel GSD using four of our 1024-pixel arrays stitched optically. They went from “we calibrate every morning and cross our fingers” to “flat-field once per season.”

In medical CT and digital X-ray, 2D photodiode arrays sit behind Gd2O2S or CsI scintillators. Low crosstalk is life-or-death — literally. We spent two years optimizing epoxy fill between pixels to get optical crosstalk below 0.02 %. A big European OEM measured 62 % reduction in ring artifacts after switching to our modules. Patient dose dropped 18 % because they could lower the X-ray tube current and still get clean images.

Si-PIN-Photodioden-Array Doppel-PD PDCA02-201

Unser Si-PIN-Photodioden-Array ist für hochpräzise Analysegeräte konzipiert. Diese TO5-Doppelfotodiode bietet eine außergewöhnliche Genauigkeit für Ihre Messanwendungen.

Decision Table: Which Photodiode Array Should You Actually Buy?

Here’s the cheat sheet we email out on first inquiry (updated Oct 2025):

| Anmeldung | Wellenlängenbereich | Recommended Array Geometry | Must-Have Spec |

|---|---|---|---|

| UV-Vis-NIR lab spectroscopy | 200–1100 nm | Linear 256–2048 px | Dark current <1 pA, AR coating |

| Process NIR / Chemometrics | 900–1700 nm | Linear InGaAs 512 px | TEC cooled, <50 pA dark |

| Hyperspectral remote sensing | 400–1000 nm | Linear 1024×1, 25 µm pitch | >98 % fill factor, low smile |

| CT / Dental CBCT | X-ray → visible | 2D 64×64 or larger tiled | Crosstalk <0.03 %, afterglow <0.1 % after 10 ms |

| OCT (swept-source or SD-OCT) | 800–1350 nm | Linear 2048 px @ 100 kHz+ | Read noise <6 e-, 140 kHz line rate |

If your specs fall somewhere in between, just send us the four numbers that matter (wavelength, speed, number of pixels, budget) and we’ll tell you the closest stock part or quote a small tweak.

The Gotchas Nobody Talks About (But We See Every Week)

- Readout noise when you multiplex too many channels onto one ADC — keep it 16:1 ratio max 64:1 unless you buy a really expensive 18-bit converter.

- Blooming on bright lines — most modern arrays have anti-blooming gates, but if you’re looking at laser lines turn integration way down or add a neutral density strip.

- Temperature gradients on large 2D panels — a 10 °C corner-to-corner difference will give you 8–10 % response drift. Use a thick copper spreader or go TEC.

- ESD — these chips hate static. Ground yourself, use ionizers, store in shielded bags. We’ve seen whole wafers killed by one careless handling.

Frequently Asked Questions (The Ones We Get Every Single Day)

Q: Will a photodiode array really replace my scientific CCD or sCMOS detector?

A: 85 % of the time, yes. If you’re doing routine analytical spectroscopy, process monitoring, or medical imaging, a PDA is faster, cheaper, more rugged, and uses 1/10th the power. Only keep the cooled CCD if you’re chasing single-photon starlight for hours.

Q: How long do these things actually last in the field?

A: We have arrays from 2015 still running 24/7 in steel-mill emission monitors. MTTF calculations (Arrhenius model, 85 °C accelerated) give >180,000 hours. Real world looks even better.

Q: Can you make weird custom stuff — staggered pixels, mixed Si/InGaAs, built-in preamps?

A: All the time. Last quarter we did a 1×720 array with every 3rd pixel UV-enhanced for a plasma diagnostic tool, and a 128×128 with integrated 12-bit ADCs on the same ceramic for a space instrument. Sketch on a napkin → prototype in 10–12 weeks is normal.

Q: What’s the price range I should budget?

A: Stock 256-pixel linear visible is usually $400–$800 in 100 pcs. Big 2D X-ray modules start around $4k–$12k depending on size and crosstalk spec. Custom work adds 30–80 %. Always cheaper than buying 256 discrete detectors and praying.

Look, if you’re tired of channel-to-channel calibration nightmares, thermal drift eating your SNR, or paying five figures for a single cooled CCD that takes 2 seconds per frame, it’s time to talk photodiode arrays.

Grab the datasheet and pricing for our most popular line right here: B2B Si-PIN-Photodioden-Array

Or just shoot us whatever mess of specs you have to info@photo-detector.com — we answer same day 99 % of the time, and samples usually ship next day if it’s stock.

You can also jump straight to the contact form: Contact Bee Photon Team