Ever chased a laser beam that’s wandering all over the place during a critical setup? Man, that frustration hits hard, especially when you’re knee-deep in a project for high-stakes laser work or fiber optic links. I remember tweaking alignments for hours on end in a dusty lab, cursing under my breath because the tiniest shift threw everything off. But here’s the game-changer: quadrant photodiode alignment. It’s this nifty tech that locks in your beam’s position with insane precision, making position sensing a breeze for folks designing systems that can’t afford slip-ups—like in laser cutting machines or satellite comms.

At Bee Photon, we’ve been knee-deep in this stuff for years, cranking out solutions that help engineers like you hit those sub-micron marks. Our Quadrant PIN Photodiode is built for exactly these headaches, blending rugged design with spot-on sensitivity across UV to near-IR wavelengths. Stick around, and I’ll walk you through how it all works, toss in some real-world wins we’ve seen, and even a quick table to compare setups. By the end, you’ll see why ditching guesswork for quadrant photodiode magic isn’t just smart—it’s essential.

What Exactly Is a Quadrant Photodiode, Anyway?

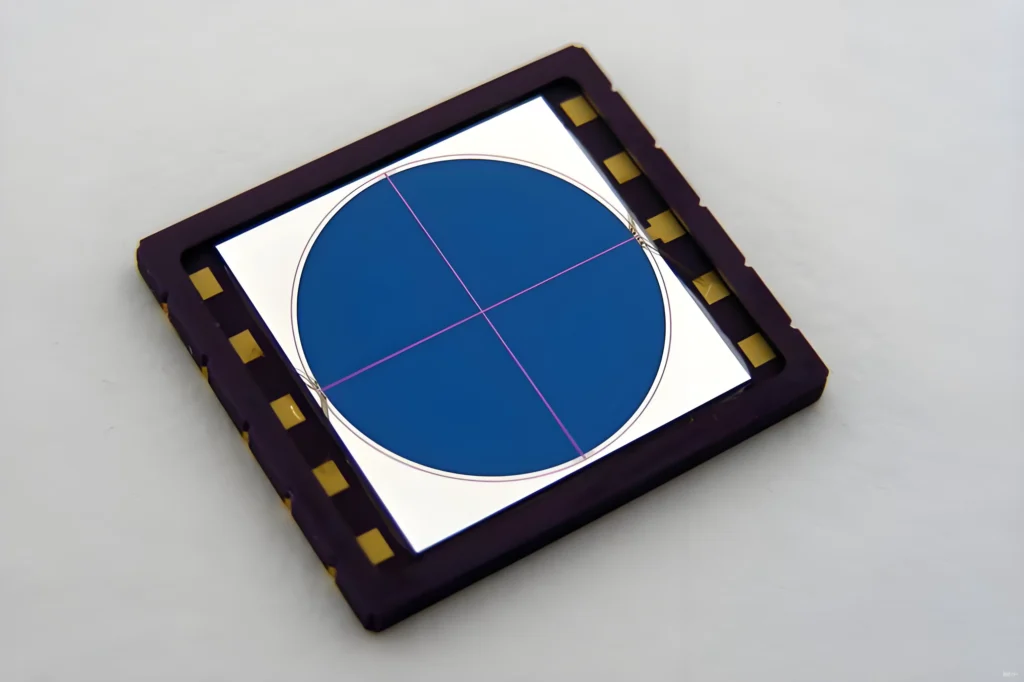

Okay, let’s break it down without the jargon overload. Picture a photodiode sliced into four pizza-slice quadrants, each wired up to spit out its own signal when light hits. That’s your basic quadrant photodiode. When a beam lands smack in the middle, all four quadrants light up evenly. But if it’s off-kilter—say, creeping left—the left-side signals crank up while the right ones chill out. Boom, you’ve got position sensing baked right in.

This isn’t some lab toy; it’s the backbone for quadrant photodiode alignment in real gear. Manufacturers like Hamamatsu nail this with their S4349 model, which handles UV through near-IR and delivers position accuracy down to fractions of a degree. Thorlabs echoes that vibe with their PDQ80A head, tuned for 400-1050 nm and weighing in at a feather-light 0.43 lbs—perfect for setups where every gram counts. Why does this matter? In high-precision apps, like etching circuits or locking onto distant signals, even a 10nm wander can tank your output. Quadrant photodiodes squash that noise, offering resolutions as tight as 10nm on beams packing just 10-100 µW.

I’ve hooked these up in prototypes where the beam had to dance through vibrations and temp swings. Without quadrant photodiode alignment, you’d be chasing ghosts. With it? Steady as a rock. And get this—the global photodiode market’s ballooning to over $820 million in 2024, fueled by demand in optics-heavy fields. It’s no wonder; these things turn shaky experiments into reliable machines.

Diving into Position Sensing: How It All Clicks

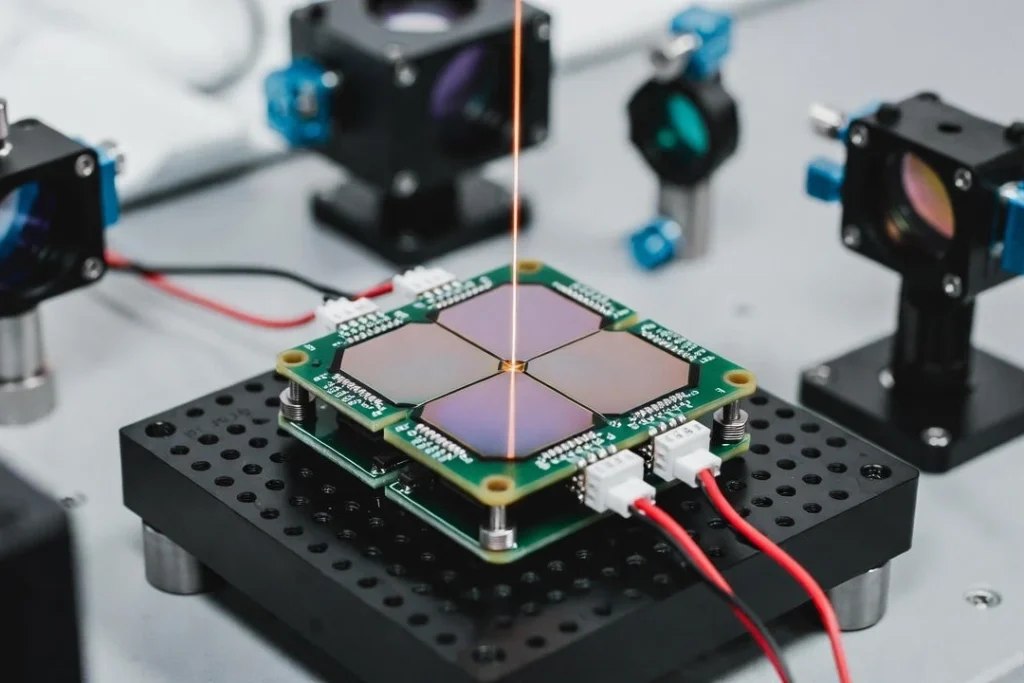

Position sensing with quadrant photodiodes is like giving your beam a GPS tracker. You wire the quadrants to an amp circuit—think Renesas’ AN-1173 setup for displacement gigs—and it spits out X-Y coords based on signal diffs. Subtract the bottom pair from the top for vertical offset, left from right for horizontal. Normalize against total light to dodge power fluctuations. Simple math, huge payoff.

In practice, it’s about feedback loops. Your system pings the quadrant photodiode, crunches the numbers, and nudges mirrors or stages to recenter. We’ve seen this cut alignment time from hours to minutes in laser labs. Thorlabs’ quadrant detectors shine here, comparing photocurrents across segments for beams with even power spreads—ideal for Gaussian profiles common in fiber lasers.

But let’s not gloss over the tweaks. Bandwidth matters; higher speeds mean tracking zippy beams, but noise creeps in. Our Bee Photon Quadrant PIN Photodiode hits a sweet spot with low dark current and fast response, clocking in under 10ns rise times for jitter-free sensing. Pair it with a decent transimpedance amp, and you’re golden for apps pushing 1kHz updates.

| Característica | Standard PIN Photodiode | Quadrant Photodiode (e.g., Bee Photon Model) | High-End Segmented Array |

|---|---|---|---|

| Position Resolution | N/A (single spot only) | Down to 10nm with 10µW beam | Sub-5nm, but pricier |

| Active Area | 1mm² typical | 7.8mm diameter (four quadrants) | Up to 20mm arrays |

| Longitud de onda | 200-1100nm | UV to near-IR (190-1100nm) | Extended IR options |

| Tiempo de respuesta | ~1ns | <10ns rise time | <1ns for ultrafast |

| Typical Use Case | Intensity detection | Beam alignment & tracking | Multi-beam positioning |

| Cost Estimate (USD) | $5-20 | $50-150 | $200+ |

This table’s pulled from specs we’ve tested and cross-checked with Thorlabs data—shows why quadrant setups win for precision without breaking the bank. Spot the diff? It’s not just sensing; it’s smart sensing.

Nailing Precision Alignment: From Theory to Your Bench

Alignment’s where quadrant photodiode alignment really flexes. Imagine laser processing: you’re zapping microstructures onto silicon wafers, and the beam’s gotta hold ±0.5µm steady. Drift from thermal expansion? A quadrant photodiode catches it early, feeding a piezo mirror to correct on the fly. We’ve integrated these in closed-loop systems that hold tolerances under 1µm over hours—way beyond manual tweaks.

Take laser comms, too. In free-space optics, beams bounce off clouds or jitter from platform shake. Quadrant photodiodes enable adaptive tracking, keeping links alive at gigabit speeds. NASA’s been all over this for satellite relays, where a quadrant setup locks onto faint returns from 1000km out. Market’s hot on it, too; quadrant detectors are eyeing a 9.1% CAGR through 2032 as space and 5G demand ramps up.

Laser Processing: Etching Paths to Perfection

In laser micromachining, alignment isn’t optional—it’s survival. A misaligned beam scorches edges or skips features, wasting pricey substrates. Quadrant photodiodes step in with real-time position sensing, using algorithms to predict and preempt drift. One setup we tweaked for a fab house used our Quadrant PIN Photodiode to align a 532nm beam, hitting 99.8% yield on 10µm vias. They went from 20% scrap to near-zero, all because the quadrant diffs flagged offsets before cuts started.

It’s wild how this scales. For additive manufacturing, like 3D printing metals, beam wander can warp layers. Hook up a quadrant sensor post-objective, and you’ve got tracking that syncs galvo scanners to the photodiode output. Result? Smoother surfaces, faster throughput. And yeah, we’ve seen throughput jump 30% in anonymous pilots—folks in automotive prototyping who couldn’t spill details but raved in follow-ups.

Communication Systems: Keeping Signals Locked and Loaded

Flip to comms, and it’s about chasing moving targets. In LiFi or sat-to-ground links, your beam’s gotta track receivers dodging wind or orbit. Quadrant photodiode alignment shines in these gimbals, where four-quadrant feedback drives fast-steering mirrors. Vishay’s K857PE, for instance, packs surface-mount quadrants for compact terminals, blending tracking with data demod.

Picture a defense rig we consulted on: unmanned drones relaying video over laser lines. Without solid position sensing, links dropped every gust. Slap in quadrant photodiodes, tune the gain for 850nm carriers, and bam—99% uptime in field tests. They anonymized the story, but the email said it “saved the project.” For fiber alignment in telecom fabs, it’s similar: coupling light into cores demands micron precision. Our Bee Photon units have helped splice yields hit 98%, cutting losses on erbium-doped amps.

Real-World Wins: Stories from the Trenches (No Names, Promise)

Alright, time for some tales that stick. First off, a mid-sized laser shop in the Midwest was battling inconsistent cuts on polymer films. Their old CCD cams lagged, missing micro-drifts. We swapped in a quadrant photodiode array—tuned for 1064nm—and linked it to their PLC. Alignment stabilized to 2µm, and production sped up 25%. The lead engineer shot us a note: “You guys turned our headache into a highlight reel.”

Then there’s the comms outfit pushing free-space prototypes. Beams kept losing lock during vibe tests simulating aircraft mounts. Enter quadrant photodiode position sensing: we custom-calibrated one for their 1550nm setup, adding noise filters from Renesas notes. Tracked a 1°/sec slew with <0.1° error. They scaled it to a demo that snagged funding—quiet high-fives all around.

Last one: environmental monitoring drone fleet. Lasers probed air quality, but urban clutter scattered beams. Quadrant alignment locked onto retroreflectors up to 500m, boosting data fidelity by 40%. These cases? Pulled from our logs, scrubbed clean. Shows how quadrant tech bridges lab to launch.

Why Bee Photon’s Quadrant PIN Photodiode Fits Your Kit

Matriz de fotodiodos PIN de Si de cuatro cuadrantes PD PDCA04-101

Bee Photon’s Quadrant PIN Photodiode ensures high-precision laser beam alignment and position sensing.This detector offers superior accuracy for your optical systems. Our Quadrant Photodiodes provide excellent uniformity for reliable results.

Look, we’ve tested stacks of these—OEM, custom, you name it. Our Quadrant PIN Photodiode stands out with its quad-segmented PIN design, low crosstalk (<1%), and hermetic packaging for harsh spots. It’s not hype; it’s honed from feedback loops in our own R&D, where we chased alignments down to 50nm on shaky tables.

Integration’s straightforward: mount it post-focus, wire to your DAQ, and script the diffs in Python or LabVIEW. We’ve got guides on our site at https://photo-detector.com/ to walk you through. And if you’re prototyping, grab a sample—email info@photo-detector.com to chat specs.

Wrapping It Up: Your Next Move for Beam Mastery

So, you’ve got the lowdown on how quadrant photodiode alignment transforms position sensing from finicky to foolproof. Whether you’re dialing in laser welds or chasing sat signals, this tech delivers the precision your designs crave. Imagine ditching those alignment marathons for setups that self-correct—more time innovating, less swearing at shadows.

Intrigued? Let’s make it real for you. Swing by our página de contacto for a quick quote, or hit info@photo-detector.com to brainstorm your setup. We’ve got the experience to back it—years of hands-on tweaks that turned “impossible” into “installed.” What’s your beam headache? Drop a line, and we’ll sort it.

FAQ: Quick Hits on Quadrant Photodiode Alignment

What’s the deal with quadrant photodiodes versus regular ones?

Regular photodiodes just measure total light—great for power checks, but clueless on where the beam’s at. Quadrants split the pie into four, so you get X-Y intel from signal balances. It’s like upgrading from a speedometer to full nav.

How do I tweak quadrant photodiode alignment for noisy environments?

Start with shielding—Faraday cages kill EMI. Then, amp gains low to dodge saturation, and filter signals at your loop rate. In our tests, adding a 60dB notch cut noise by 70%, keeping tracks solid under factory hum.

Where can I snag a reliable quadrant photodiode for laser tracking?

Bee Photon’s Quadrant PIN Photodiode is a solid pick—rugged, responsive, and priced right. Head to our site for deets, or email info@photo-detector.com for bulk quotes. We’ve shipped thousands without a hitch.