Imagine you’re building an AI robot that has to navigate a factory floor filled with dust or even a warehouse where a small fire kicked up some smoke. Your regular camera just blanks out, right? The robot stops dead, confused and useless. That’s where short-wave infrared, or SWIR, comes in handy. And the star player here? InGaAs photodiodes for SWIR sensing. These little guys let robots see thru smoke, fog, or haze like it’s not even there, while also spotting differences in materials that visible light totally misses.

At Bee Photon, we’ve been working with these sensors for years, helping robot makers solve exactly those tough problems. Whether it’s sorting plastics on a conveyor belt or guiding autonomous bots in tricky environments, InGaAs photodiode applications in SWIR robotics are changing the game. Let’s dive into why they’re such a big deal, especially if you’re a robot manufacturer looking for reliable machine vision sensors.

What Makes SWIR Sensing So Special for AI Robots?

Visible light cameras are great in clear conditions, but throw in some smoke or dust and they’re blind. SWIR wavelengths – roughly 900 to 1700 nanometers – behave differently. They scatter way less off small particles, so they penetrate obscurants better. Studies from places like SPIE conferences have shown over and over that SWIR imaging cuts through fog, smoke, and haze much clearer than visible or even near-infrared.

Think about a firefighting robot or one inspecting a smoky industrial site. Regular sensors fail, but SWIR lets it keep going, spotting hot spots or obstacles. We’ve seen this firsthand in projects where robots needed to operate reliably in real-world messiness.

And it’s not just about seeing through stuff. SWIR is awesome for material identification because different substances reflect SWIR light uniquely. Water absorbs it strongly, plastics reflect differently – that kinda thing. For machine vision sensors in robotics, this means sorting recyclables, detecting defects, or even identifying food quality on the fly.

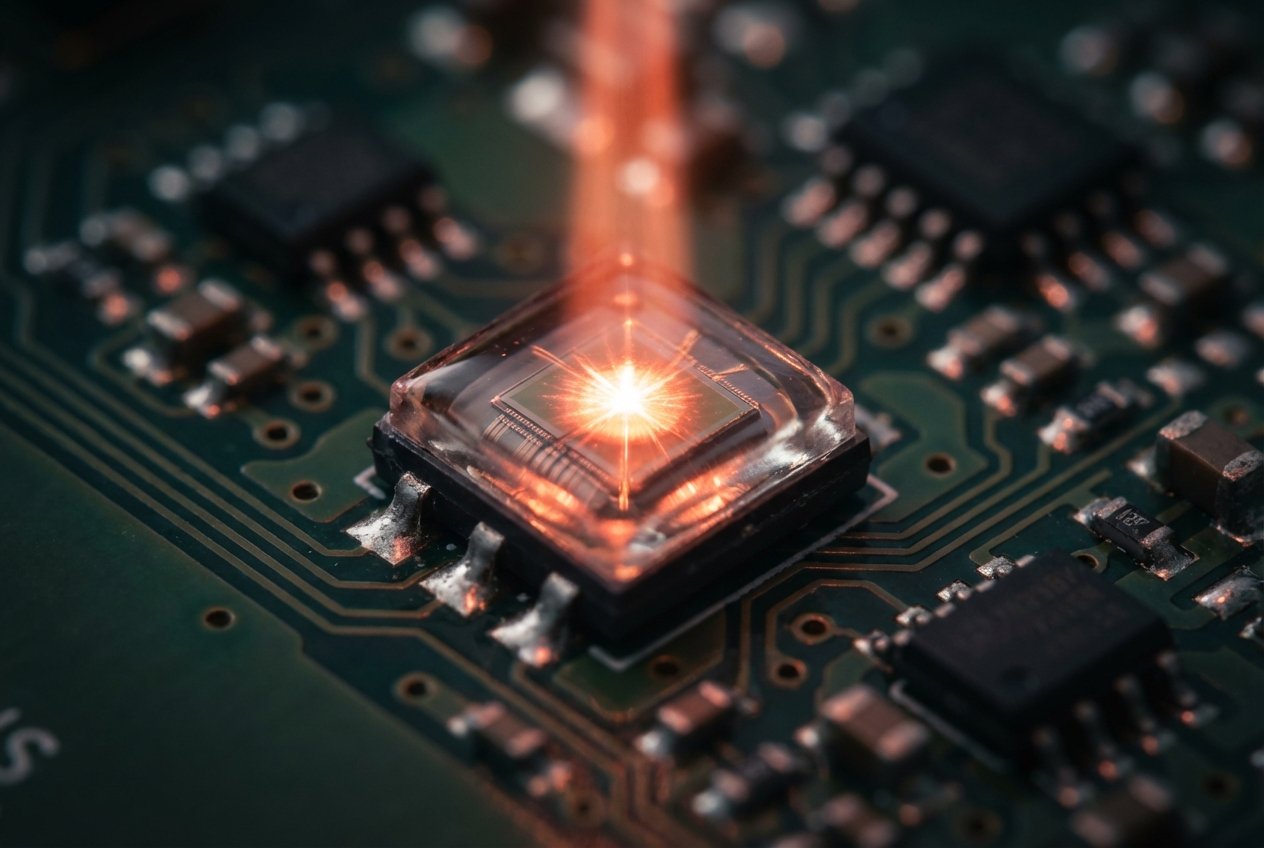

800-1700nm InGaAs PIN Photodiode PDIT05-222N

Maximize signal detection with our High Responsivity InGaAs Detector.Bee Photon offers this sensitive photodiode for precise measurement in spectroscopy and medical diagnostics.

Diving Deeper: How InGaAs Photodiodes Power SWIR in Robotics

InGaAs stands for indium gallium arsenide, a material that’s perfect for detecting SWIR light. Silicon photodiodes top out around 1100nm – beyond that, they’re basically transparent and useless. InGaAs picks up right where silicon leaves off, offering high sensitivity up to 1700nm or even 2600nm in extended versions.

These photodiodes convert SWIR photons into electrical signals super efficiently. Low noise, high detectivity – they count individual photons in some cases. That’s why they’re the go-to for high-performance SWIR robotics.

Here’s a quick comparison to show why robot builders switch to InGaAs:

| Feature | Silicon Photodiodes | InGaAs Photodiodes |

|---|---|---|

| Wavelength Range | Up to ~1100nm | 900-1700nm (standard), up to 2600nm extended |

| Sensitivity in SWIR | None – transparent beyond 1100nm | Extremely high, photon-counting capable |

| Smoke/Fog Penetration | Poor – heavy scattering | Excellent – reduced Mie scattering |

| Material Identification | Limited to visible cues | Strong – unique spectral signatures |

| Typical Applications | Standard visible machine vision | SWIR robotics, hyperspectral imaging |

| Operating Temperature | Room temp fine | Often cooled for best performance, but room-temp options available |

| Cost | Lower | Higher, but worth it for demanding tasks |

(Data drawn from sources like Teledyne Vision Solutions and AZoSensors reports on InGaAs properties.)

The market backs this up too. The global SWIR market was around USD 603 million in 2024 and is projected to hit over USD 1.1 billion by 2030, according to Grand View Research. A big chunk of that growth? Industrial automation and robotics pushing for better vision in tough spots.

Real Advantages: Smoke Penetration and Material Recognition in Action

Let’s talk smoke penetration first. Visible light bounces off smoke particles like crazy, but SWIR wavelengths are longer, so they slip through. Field tests, like those shown in forest fire imaging from Sensors Unlimited, reveal flames clearly where visible cameras just show a wall of smoke. For robots, this translates to safer navigation in hazardous areas – think search-and-rescue bots or ones in manufacturing plants with welding fumes.

Then there’s material ID. In SWIR, things like plastics, fabrics, or even moisture content pop out because of their absorption bands. One example: sorting black plastics in recycling. Visible light sees them all as black, but SWIR differentiates them easily. We’ve helped clients integrate InGaAs photodiode applications for exactly this – robots that sort waste faster and more accurately.

Another perk? Night vision without extra lights. SWIR captures nightglow – that faint atmospheric illumination – letting robots operate in low light without blinding anyone with visible floods.

SWIR Robotics in the Real World: Some Stories We’ve Seen

Over the years at Bee Photon, we’ve worked on projects that really highlight this tech. One robot manufacturer was building autonomous vehicles for warehouses prone to dust and occasional haze from machinery. Their visible cameras kept failing, causing downtime. Switching to our InGaAs-based SWIR sensors let the bots see clearly, reducing errors by a huge margin – they reported smoother operations almost right away.

In another case, a client in food processing needed to detect contaminants or moisture on conveyor belts. Regular sensors missed subtle differences, but SWIR machine vision sensors nailed it, spotting issues that could’ve led to recalls. No names, of course, but these kinds of wins keep us excited about pushing InGaAs photodiodes further.

Industrial automation is exploding with this. Reports from LinkedIn market analyses point to machine vision as a top driver for InGaAs SWIR photodiodes, especially for defect detection and quality control.

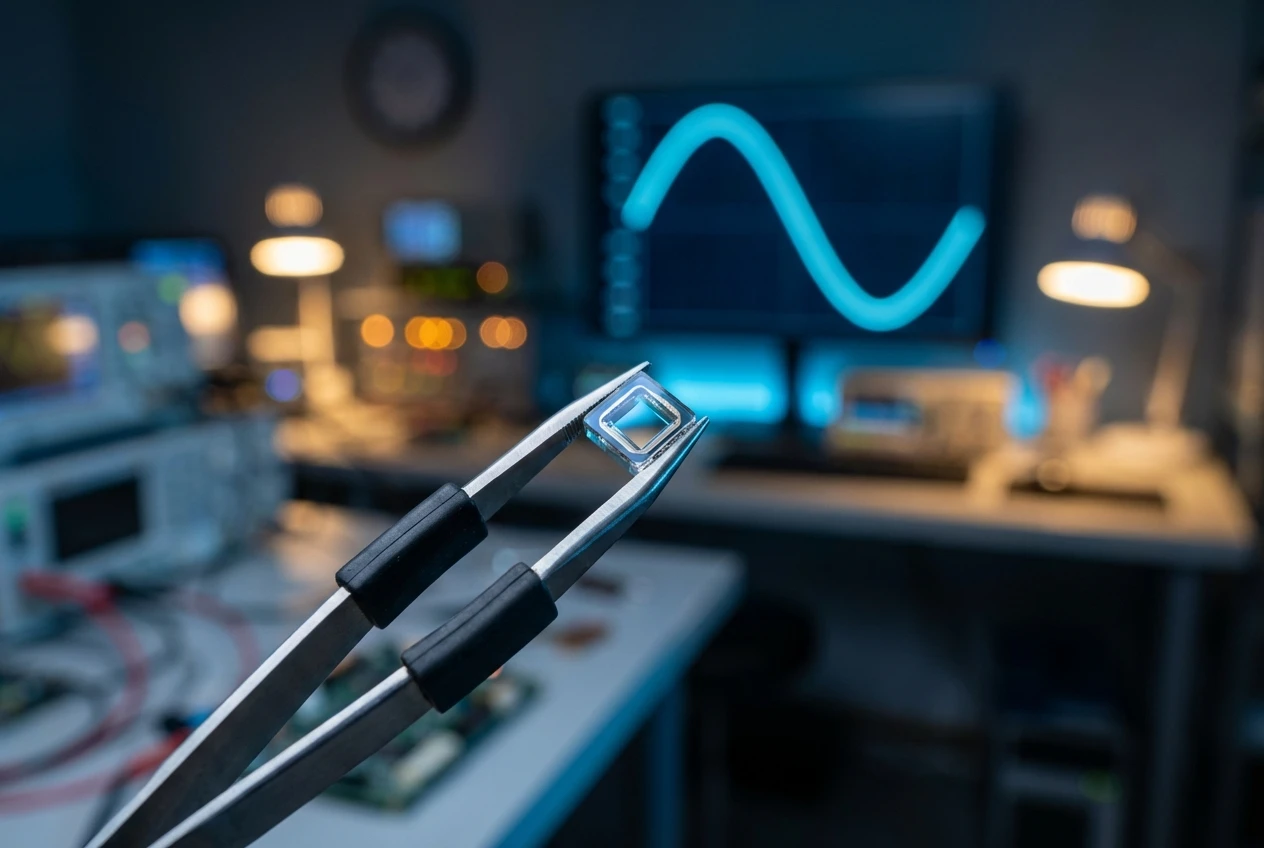

800-1700nm InGaAs PIN Photodiode PDIT005-224A

Bee Photon’s TO-18 InGaAs PIN Photodiode delivers exceptional performance for industrial sensing and control. This robust photodiode offers high reliability for your most critical applications.

Picking the Right InGaAs Photodiodes for Your Robot Project

Not all sensors are equal. Look for low dark current, high quantum efficiency, and options for cooling if you need ultra-low noise. At Bee Photon, our lineup focuses on robust, easy-to-integrate modules tailored for robotics. Check out our products at https://photo-detector.com/ – we’ve got options from basic photodiodes to full arrays.

Factors to consider:

- Resolution and pixel size for your field of view

- Frame rates for fast-moving robots

- Integration with AI algorithms – SWIR data pairs beautifully with machine learning for smarter recognition

We’ve got experience tweaking these for specific needs, like extended wavelength for deeper material insights.

Why Bee Photon for Your SWIR Needs?

We’ve been deep in photodetector tech for a while now, specializing in high-quality InGaAs solutions. Our stuff is built tough for real industrial use, and we back it with solid support. If you’re tired of sensors that choke in smoke or can’t tell materials apart, let’s talk.

Frequently Asked Questions About InGaAs Photodiodes for SWIR in Robotics

What’s the big difference between SWIR and regular visible sensing for robots?

SWIR cuts through smoke, fog, and dust way better, plus it reveals material differences that visible light hides. Perfect for robots in messy environments.

Why choose InGaAs over other SWIR materials?

InGaAs offers the best balance of sensitivity, low noise, and reliability in the 900-1700nm range. It’s the industry standard for a reason – proven in everything from machine vision to defense.

Can these sensors really help with material identification in robotics?

Absolutely. Things like plastics, water content, or even bruises on produce show up clearly in SWIR. We’ve seen robots sort stuff visible cameras couldn’t touch.

Are InGaAs photodiodes expensive for robot projects?

They cost more upfront than silicon, but the reliability and fewer failures pay off quick in demanding apps. Market growth shows more folks agreeing.

How do I get started with SWIR for my robots?

Drop us a line! Head to our contact page at https://photo-detector.com/contact-us/ or email info@photo-detector.com for a quote or chat about your setup.

If SWIR robotics sounds like the upgrade your AI bots need, reach out to Bee Photon today. We’d love to hear about your challenges and see how our InGaAs photodiodes can help. Let’s make your robots see better – even when conditions aren’t perfect.