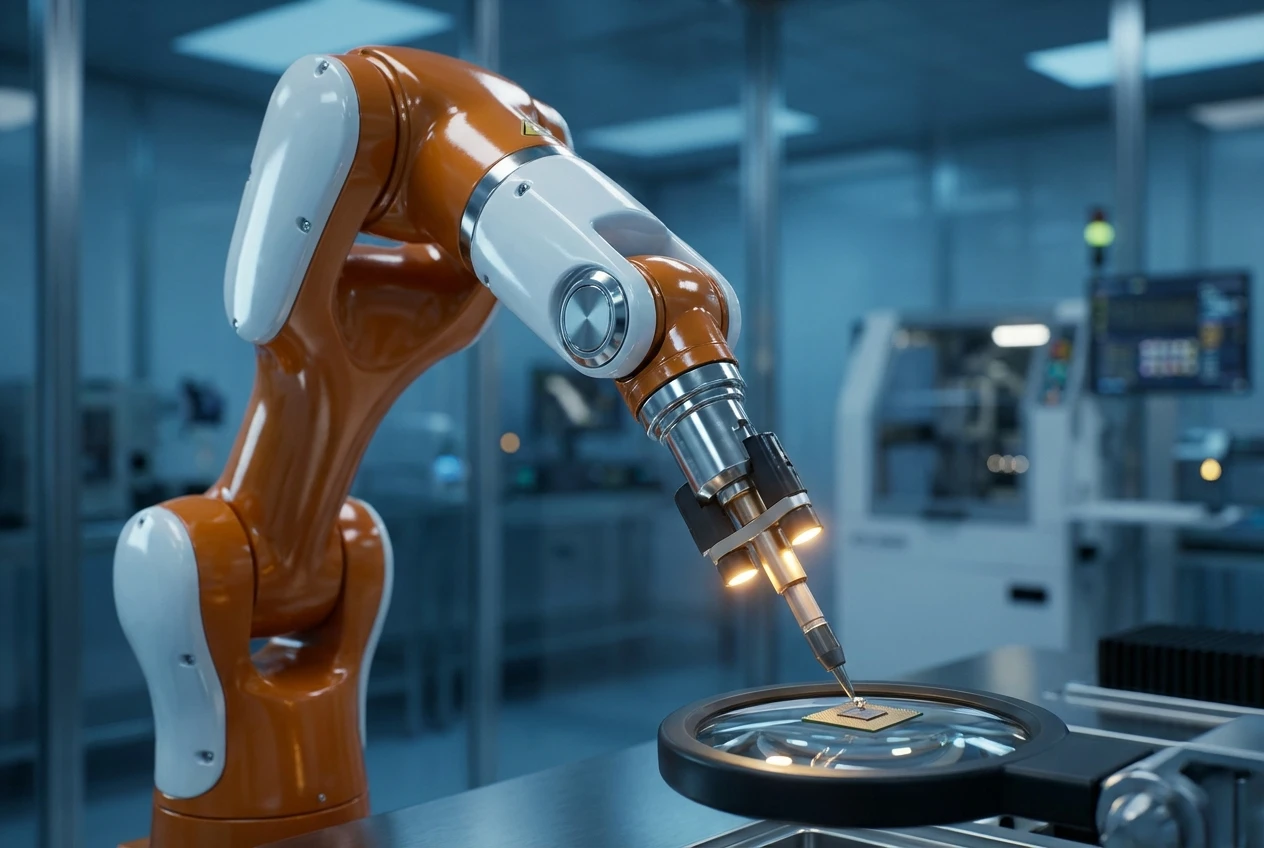

There is nothing more frustrating in the industrial automation world than a robot arm that’s got the “jitters.” You know what I’m talking about. You spend weeks programming the kinematics, you think your PID loops are solid, and yet, the end-effector misses the target by a fraction of a millimeter.

Is it the motor? Maybe. Is it the driver? Doubt it.

Nine times out of ten, when I’m debugging a client’s rig, the problem lies in the feedback loop. Specifically, the eyes of the system. If your robotics encoders aren’t reading the position fast enough or clean enough, your robot is effectively blind.

Today, I want to talk about the unsung hero of this process: Encoder Photodiodes. We aren’t going to talk about generic theory here. I want to dive into why specific photodiode characteristics (like capacitance and rise time) determine whether your robot is a surgical instrument or a sledgehammer.

The “Dirty Secret” of Motion Control Sensors

Here’s the thing about motion control sensors. A lot of manufacturers treat them like a commodity. They slap a cheap phototransistor into an optical encoder assembly and call it a day.

For a garage door opener? Sure, that works. For a 6-axis industrial arm moving at 2 meters per second? That’s a recipe for disaster.

I remember consulting for a mid-sized integration firm last year. They were building a pick-and-place machine for a semiconductor fab. High stakes, expensive wafers. They were losing their minds because the Z-axis kept overshooting. They blamed the servo tuning. I took one look at their encoder spec sheet and saw the issue immediately. They were using sensors with a rise time of 15 microseconds.

In the world of high-speed automation, 15 microseconds is an eternity.

We swapped those out for high-speed Encoder Photodiodes (specifically Si PIN types), dropped the rise time to nanoseconds, and the overshoot vanished. The physics didn’t change, but the data integrity did.

Why Si PIN Photodiodes Are the Gold Standard

If you are building robotics encoders, you generally have two choices for the detector: Phototransistors or Photodiodes.

Let me save you some time: If you care about precision, forget phototransistors. They have high gain, sure, but they are slow and temperature-dependent.

For robotic arm positioning, we need speed and linearity. This is where Silicon PIN (Si PIN) photodiodes shine.

1. Speed (Rise and Fall Time)

An optical encoder works by chopping light. A disk with slits spins between an LED and a detector. If the detector can’t switch from “dark” to “light” fast enough, the square wave signal turns into a messy, sloping triangle wave. Your controller gets confused, counts are missed, and your position data is toast.

Si PIN photodiodes have a thick intrinsic layer (the ‘I’ in PIN) that reduces junction capacitance. Lower capacitance means faster speed.

The formula for bandwidth (f_BW) roughly looks like this:

f_BW = 0.35 / t_r

Where t_r is the rise time. If you use a slow sensor, your bandwidth is choked. You literally cannot spin the motor faster without losing position data.

2. Linearity and Dynamic Range

In motion control sensors, you want a linear relationship between the light hitting the sensor and the current coming out. Encoder Photodiodes offer excellent linearity over a wide range (often 6 to 7 decades). This means even if the LED dims slightly over years of use, the signal profile remains consistent.

3. Dark Current (Noise)

You want the sensor to read zero when it’s dark. But physics is messy. There is always some leakage current, called Dark Current (I_d). In high-temperature industrial environments (like inside a welding robot), this can increase.

High-quality Si PIN diodes, like the ones we engineer at BeePhoton, are optimized to keep I_d incredibly low, ensuring that “off” really means “off.”

Si PIN photodiode PDCP08 Series PDCP08-501

High-Performance Detection: The PDCP08-501 is a high-speed Silicon PIN Photodiode with a transparent window.

Key Specs: Featuring a 2.9×2.9mm active area, this PIN photodiode offers low dark current and high responsivity, making it an ideal sensor for general optical switches and light detection systems.

Technical Deep Dive: Selecting the Right Diode

Okay, let’s get technical. When you are sourcing components for your encoders, what parameters actually matter?

I see engineers looking at “Peak Sensitivity Wavelength” and stopping there. That’s a mistake. Here is what you should be looking at if you want to dominate the robotics encoders market.

Junction Capacitance (C_j)

This is the enemy of speed. The larger the active area of the photodiode, the higher the capacitance. But, you need a large enough area to align with the encoder disk slots. It’s a trade-off.

Current generated (I_p) is calculated as:

I_p = P_opt * R_lambda

Where:

P_opt= Optical Power incident on the diodeR_lambda= Responsivity at wavelength lambda

You need to balance the size (to get enough P_opt) with the capacitance. At BeePhoton, we often recommend array detectors or segmented photodiodes for absolute encoders, which help balance this trade-off. You can check out our specs on our Si PIN photodiodes page to see how we handle this geometry.

Response Time vs. Reverse Bias

Here is a trick not everyone knows. You can make a photodiode faster by applying a reverse bias voltage (V_R).

Increasing V_R increases the width of the depletion region, which decreases capacitance (C_j).

C_j is proportional to (V_R)^-0.5 (roughly)

So, if your robotic arm positioning is lagging, sometimes you don’t need a new sensor—you might just need to increase the bias voltage on your current Encoder Photodiodes (within limits, of course, or you’ll fry it).

Comparison: Photodiode vs. The Alternatives

I put together this table to make it crystal clear why I push for PIN diodes in automation.

| Feature | Phototransistor | Standard PN Photodiode | Si PIN Photodiode (Recommended) |

|---|---|---|---|

| Speed (Rise Time) | Slow (µs range) | Medium | Fast (ns range) |

| Gain | High (Internal gain) | 1 (No gain) | 1 (No gain) |

| Temperature Stability | Poor | Good | Excellent |

| Linearity | Poor | Good | Excellent |

| Best Use Case | Vending machines, simple counting | Low-speed conveyors | Robotics Encoders, CNC machines |

It’s pretty obvious. If you are building a collaborative robot (cobot) that needs to detect resistance and stop immediately for safety, you cannot afford the lag of a phototransistor.

Si PIN photodiode PDCP08 Series PDCP08-502

The PDCP08-502 is a high-response 2.9×2.8mm Silicon PIN Photodiode designed for precision photoelectric applications. Featuring low junction capacitance, low dark current, and a wide spectral range (340-1100nm), it is the ideal component for optical switches and compact sensing modules requiring stable and fast signal output.

Real World Scenario: The Vibrating Arm

Let’s look at an anonymous case I handled recently. A manufacturer of SCARA robots was seeing a weird issue. When the arm came to a stop, it would “buzz.” It wouldn’t hold position perfectly.

They thought it was mechanical backlash. They tightened the gearboxes. Still buzzed.

We hooked up an oscilloscope to the encoder output. The signal from their sensors (generic photodiodes from a catalog distributor) was noisy. The “edges” of the square wave were fuzzy. The servo driver was reading this noise as movement, so it kept trying to correct the position back and forth hundreds of times a second. That was the buzz.

We retrofitted the encoder assembly with precision Encoder Photodiodes. The signal edges sharpened up immediately. The driver stopped fighting the noise. The buzz stopped.

The cost difference per diode? Maybe 50 cents. The value of a robot that doesn’t vibrate? Priceless.

Integration Tips for Engineers

If you are designing the PCB for the encoder, keep these tips in mind. I’ve learned these the hard way so you don’t have to.

- Transimpedance Amplifiers (TIA): Since photodiodes produce current, not voltage, you need a TIA. Place this amp as close to the Encoder Photodiodes as physically possible. I mean millimeters. Long traces act like antennas and pick up EMI from the robot motors.

- Shielding: Industrial environments are dirty with electromagnetic noise. Shield your optical module.

- Light Collimation: Your photodiode is only as good as the light hitting it. Ensure your LED source is collimated. If the light spreads too much, it bleeds across multiple slots in the encoder disk, reducing contrast.

Why BeePhoton?

Look, I’ve been in this industry a long time. I’ve seen sensors fail because of humidity, vibration, and just poor manufacturing.

At BeePhoton, we focus specifically on the needs of high-end instrumentation and automation. We don’t just sell you a diode; we help you figure out the capacitance and spectral response you need for your specific motion control sensors.

When you are ready to stop guessing and start measuring with precision, visit us at https://photo-detector.com/. We handle everything from standard Si PINs to custom arrays for absolute encoders.

Future Trends in Optical Encoders

We are seeing a shift toward higher resolution without increasing the disk size. This requires Encoder Photodiodes with smaller active areas but higher sensitivity. It’s a tough balance.

Also, reflective encoders are gaining traction over transmissive ones for compact robotics. This changes the geometry of the sensor, requiring the emitter and detector to be on the same plane. It makes the optics harder, but the space savings are huge for medical robotics.

Si PIN photodiode PDCP08 Series PDCP08-511

The PDCP08-511 is a high-performance Black Epoxy PIN Photodiode designed for precision infrared applications. Encased in a special black epoxy resin, this sensor effectively acts as a daylight filter, blocking visible light interference while maximizing sensitivity at 940nm. With a large 2.9×2.9mm active area and low dark current, it ensures reliable signal detection for optical switches and remote control systems, even in noisy ambient light environments.

FAQ: Common Questions on Encoder Photodiodes

Q: Can I use a regular photodiode for an incremental encoder?

A: Technically, yes, but I wouldn’t recommend it for anything moving fast. Standard PN photodiodes have higher capacitance than PIN photodiodes. For robotics encoders, this limits your max RPM. Stick to Si PIN types for motion control.

Q: How does temperature affect the encoder signal?

A: All semiconductors are affected by heat. However, Encoder Photodiodes (Si PIN) are much more stable than phototransistors. The main issue is usually the dark current increasing with heat. If your robot operates in hot environments (>80°C), let us know so we can select a chip with extremely low dark current characteristics.

Q: Do you offer custom photodiode arrays for absolute encoders?

A: Yes, we do. Absolute encoders require multiple tracks and specific sensor spacing. We can customize the pitch and active area of the array to match your code wheel design perfectly. Reach out to our engineering team at info@photo-detector.com to discuss specs.

Q: What is the lifespan of these sensors?

A: The Encoder Photodiodes themselves are solid-state and can last practically forever if kept within voltage/current specs. The point of failure in an optical encoder is usually the LED dimming over time, not the photodiode failing.

Final Thoughts

Precision isn’t an accident. It’s engineered.

If your industrial robots are struggling with positioning accuracy, stop blaming the code. Take a hard look at the Encoder Photodiodes inside your motors. High-quality, low-capacitance sensors are the cheapest upgrade you can make for a massive performance boost.

Don’t let crappy sensors bottleneck your million-dollar machine.

Ready to upgrade your motion control?

- Check out our products: Browse our range of Si PIN photodiodes.

- Get Advice: Not sure which sensor fits your geometry?

- Contact Us: Drop us a line at https://photo-detector.com/contact-us/ or email

info@photo-detector.com.