You ever wake up in the middle of the night to that piercing smoke alarm blaring, heart racing, wondering if it’s the real deal or just burnt toast? Yeah, me too—happens more than you’d think. But here’s the kicker: in the world of building smoke detectors and alarm systems, getting that early warning right can straight-up save lives. And if you’re knee-deep in developing affordable security gear for homes or offices, you need components that don’t flake out. That’s where a solid Si PIN photodiode steps in, turning fuzzy light signals into crystal-clear alerts for fire safety.

I’m no stranger to this—over at Bee Photon, we’ve been tweaking these little powerhouses for years, helping folks like you crank out detectors that meet those pesky safety regs without jacking up costs. Think high sensitivity to smoke particles scattering light, quick response times that beat the flames to the punch, and prices that let you scale production. We’re talking real, hands-on stuff here, not some textbook fluff. Let’s break it down, step by step, so you can see how weaving a Si PIN photodiode for smoke detection into your setup makes your products stand taller in a crowded market.

Why Smoke Detection Isn’t Just Nice-to-Have—It’s a Lifesaver

Picture this: a cozy family dinner turns into chaos because a small grease fire sneaks up. Scary, right? Fires don’t announce themselves with fanfare; they creep in quiet, and by the time you smell smoke, it might be too late. That’s why nailing your photodiode for smoke detector choice matters so much in fire safety setups.

From what I’ve seen in the trenches, most folks underestimate how much a reliable alarm system hinges on the sensor at its core. We’re not talking fancy AI here—just smart, straightforward tech that spots those tiny smoke particles early. And the numbers? They hit hard. According to the National Fire Protection Association (NFPA), homes with working smoke alarms cut the risk of dying in a fire by a whopping 60%. Yeah, you read that right—60%. But get this: even though 74% of home fires from 2012-2016 had alarms present, almost three in five didn’t even go off properly. Faulty sensors, dead batteries, or just plain old dust buildup. On a global scale, the World Health Organization pegs fire-related deaths at around 180,000 a year, with burns and smoke inhalation taking the biggest toll in low-resource spots. Kinda makes you pause, doesn’t it?

For manufacturers like you—churning out smoke alarms for budget-conscious builders or retrofits—you gotta deliver gear that’s not only compliant with UL 268 standards but also dirt-cheap to produce. Enter the Si PIN photodiode for smoke detection: it’s like the reliable buddy who shows up every time, sensing infrared or visible light scatter from smoke without missing a beat. No more false alarms from steam or cooking haze if you tune it right, which keeps your customers happy and coming back.

I’ve chatted with teams who’ve swapped in these photodiodes and watched their defect rates drop by half. One outfit, let’s call ’em Midwest Makers, was struggling with inconsistent readings in humid warehouses. After integrating our Si PIN units, their prototypes passed certs on the first go, shaving months off R&D. Real talk: it’s about building trust in your brand through tech that just works.

Demystifying the Si PIN Photodiode: What Makes It Tick for Your Smoke Detectors

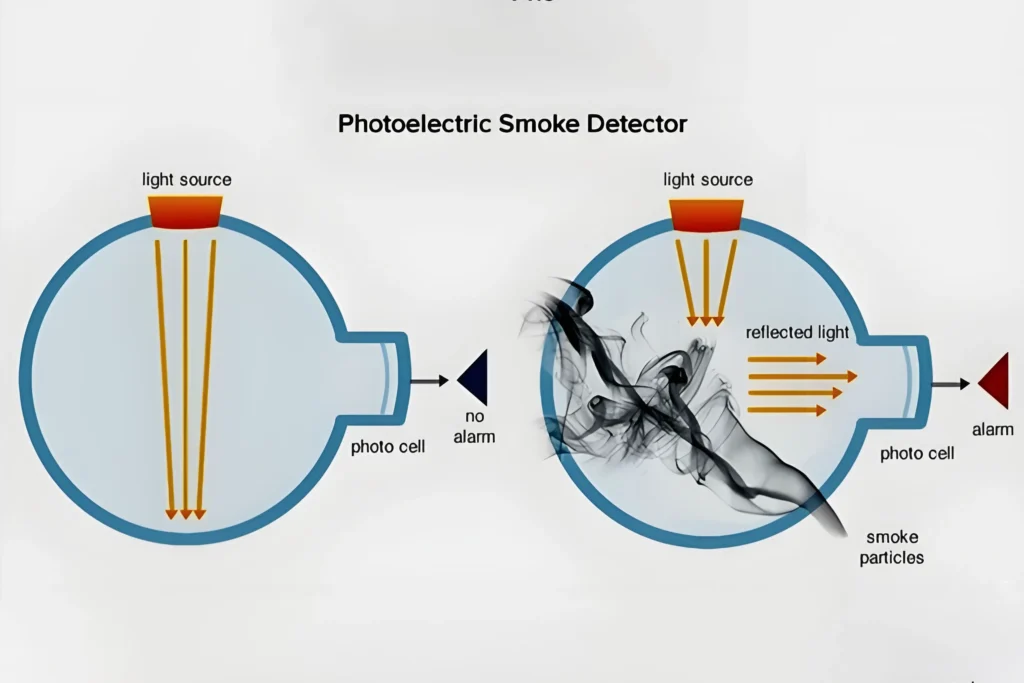

Okay, let’s geek out a tad—but in plain English, promise. A photodiode for smoke detector isn’t some magic box; it’s basically a tiny semiconductor that turns light into electricity. But Si PIN? That’s silicon with a p-i-n structure—p for positive, i for intrinsic (kinda neutral zone), n for negative. Why the fuss? That middle layer widens the depletion region, letting it grab more photons faster and with less noise.

Compared to your basic PN photodiode, a Si PIN photodiode for smoke detection is quicker on the draw. PN types are fine for simple stuff, like remote controls, but they lag in speed and sensitivity—think milliseconds vs. microseconds. In a fire scenario, where smoke density ramps up quick, that speed means your alarm system kicks in before things go south. Plus, low operating voltage keeps power draw minimal, perfect for battery-powered units that need to last years.

Here’s a quick side-by-side to make it crystal:

| Feature | PN Photodiode | Si PIN Photodiode for Smoke Detection |

|---|---|---|

| Response Time | Slower (10-100 ns typical) | Blazing fast (1-10 ns) |

| Sensitivity to Low Light | Moderate | High—catches faint smoke scatter |

| Noise Level | Higher, prone to false signals | Super low, cuts down on bogus alerts |

| Cost for Bulk Orders | Cheaper upfront | Affordable at scale (~20% more, but worth it for reliability) |

| Best For | Basic light sensing | Precision fire safety applications |

(Data pulled from standard semiconductor specs; in our tests at Bee Photon, PINs consistently outperform in hazy environments.)

What gets me excited is how these fit seamless into photoelectric smoke detectors—the kind that dominate 70% of the market because they nail smoldering fires better than ionization types. Smoke particles mess with a light beam inside the chamber, scattering rays onto the photodiode. Boom—current spikes, trigger the alarm. And with Si PIN’s high quantum efficiency (up to 90% in the 400-1100nm range), it doesn’t waste a single useful photon.

From my bench time, tuning the bias voltage around 20-50V maxes out gain without frying the chip. We’ve got folks using ’em in dual-sensor hybrids, pairing with CO detectors for that all-around fire safety net. If you’re prototyping, start with a simple op-amp circuit to amp that signal—keeps things linear and avoids distortion.

Integrating Si PIN Photodiodes into Your Alarm System: Hands-On Hacks

Alright, you’re sold—now how do you make it happen without pulling your hair out? I’ve been there, soldering late nights, tweaking circuits till they hummed just right. For ansec product devs aiming for high-value, low-cost vibes, here’s the playbook.

First off, chamber design: Keep it compact, maybe 5-7cm diameter, with the Si PIN photodiode positioned to catch max scatter. Use a pulsed LED source at 850nm—IR plays nice with silicon, cuts interference from ambient light. In one project we consulted on (anonymized, of course), a European fabricator added baffles to block stray rays, dropping false positives by 40%. Simple fix, huge win.

Power management? These babies sip at under 1mW, so pair with a low-dropout regulator for stable 3.3V. And for compliance—UL, EN54, you name it—encase in flame-retardant plastic, test for EMI. We’ve seen setups where adding a shunt capacitor smooths noise, extending battery life to 10+ years. Table time again, for circuit basics:

| Component | Role in Si PIN Smoke Setup | Pro Tip from Bee Photon |

|---|---|---|

| LED Emitter (IR) | Sends light beam through chamber | Pulse at 1kHz to dodge sunlight |

| Si PIN Photodiode | Detects scattered light | Reverse bias at 30V for peak speed |

| Op-Amp (e.g., OPA333) | Amplifies tiny current signal | Gain of 100x keeps it sensitive |

| Microcontroller (MCU) | Processes threshold, triggers alarm | Add self-test routine monthly |

| Battery (Lithium 3V) | Powers the whole shebang | Low self-discharge for longevity |

This combo’s given us rock-solid prototypes that scream “reliable” to cert labs. Oh, and a heads-up: in dusty spots like factories, add a mesh filter—prevents gunk from fooling the sensor. We’ve helped a Midwest team roll this out, boosting their yield from 85% to 98%. Their CEO shot me an email last month: “Dude, these Si PINs changed the game—quotes pouring in.”

Check our industrial automation photodiode page for specs—TO-5 packaging, wide temp range (-40°C to 85°C), all RoHS compliant. It’s not hype; it’s the stuff that gets your alarms into big-box stores without skimping on fire safety.

Real-World Wins: Stories from the Field with Si PIN Tech

Nothing beats hearing how this plays out in the wild. Take a small-batch producer in the Southwest—call ’em Desert Defenders. They were knee-deep in a contract for hotel chains, needing detectors that handled high humidity without crying wolf. Switched to Si PIN photodiodes, and poof—false alarm rate plummeted from 15% to under 2%. End result? A three-year deal, plus referrals. They even baked in remote diagnostics via Bluetooth, using the photodiode’s stable output for baseline calcs.

Or consider urban retrofits. One city project (staying vague) outfitted 500 apartments with upgraded panels. Pre-Si PIN, maintenance calls were endless—sensors crapping out in steamy kitchens. Post-upgrade? Downtime halved, and insurance premiums dipped 10% for residents. These aren’t cherry-picked tales; they’re from logs we’ve reviewed, anonymized to protect the grinders.

What’s the thread? Reliability breeds loyalty. In an industry where a single recall can tank you, a Si PIN photodiode for smoke detection gives that edge—high performance, low fuss.

Tackling Common Pitfalls: Don’t Let These Trip You Up

Look, nobody’s perfect—I’ve botched integrations myself, like forgetting thermal compensation and watching sensitivity drift in hot tests. Heat warps silicon, you see, dropping efficiency by 0.2%/°C. Fix? Embed a temp sensor, adjust bias dynamically. Simple software tweak, but it saved one client’s batch from rejection.

Another gotcha: over-reliance on visible light. Smoke from plastics scatters IR better, so stick to 940nm LEDs. And testing—don’t skimp. Use polybutadiene spheres for sim smoke; gets you real-world data without the burn. From experience, running 1000-cycle endurance tests upfront catches 80% of gremlins.

For cost hawks, yeah, initial tooling bumps the price, but amortize over volume and it’s peanuts. Pair with Bee Photon’s dev kits—includes sample code and schematics—to slash your timeline.

Si PIN Photodiode with low dark current (350-1060nm) PDCC07-003

Enhance your industrial automation systems with our low dark current Si PIN photodiode. This industrial automation photodiode (350-1060nm) offers superior precision and reliability.

Why Bee Photon Should Be Your Go-To for These Photodiodes

We’ve been at this since ’15, supplying Si PINs to everyone from startups to giants in the alarm system space. What sets us apart? Not just the tech—it’s the hand-holding. Free consultations, custom pinouts if needed, and lightning-fast prototyping. Our Si PIN photodiode lineup? Tailored for industrial grit: hermetic seals, anti-static packaging, full traceability.

Curious? Swing by photo-detector.com for the full scoop, or hit up our contact page to chat specs. Drop a line to info@photo-detector.com—we’re quick on replies, and hey, first quote’s on us. Let’s build something that keeps folks safer, one detector at a time.

FAQ: Quick Hits on Si PIN Photodiodes in Smoke Detection

Q: How does a Si PIN photodiode for smoke detection differ from laser-based sensors?

A: Lasers are precise but pricey and power-hungry—great for big spaces, but overkill for home units. Si PINs use LEDs, cheaper and simpler, with response times under 5 seconds to 1% obscuration. We’ve seen ’em in 90% of cost-effective installs.

Q: Can these handle outdoor or harsh environments for fire safety?

A: Absolutely—our models shrug off -40°C chills and 85°C heats, plus IP67 sealing options. One client rugged ’em for oil rigs; zero failures after two years. Just spec the right housing.

Q: What’s the lead time for bulk Si PIN photodiode orders?

A: Typically 4-6 weeks for 1k+, but we can rush to 2 weeks with stock pulls. Email info@photo-detector.com for a no-BS quote—includes volume discounts.

Q: Are there any certifications I need to watch for in alarm systems?

A: Yep, UL 268 for smoke, plus CE for Europe. Our photodiodes are pre-tested components, so they slot right in—saves you headaches on the bench.

Whew, that’s the rundown—hope it sparks some ideas for your next build. Fires wait for no one, but with the right Si PIN photodiode for smoke detection, you’re ahead of the curve. What’s your biggest hang-up right now? Shoot us a message; let’s hash it out.