If you’ve ever messed around with off-the-shelf phototransistors and thought, “this almost works, but if only the window filtered out more visible light” or “why can’t the pins fit my board layout better,” you’re not alone. I’ve been there too – tweaking prototypes late at night, wishing for something that just fits the application perfectly. That’s where customizing comes in. At Bee Photon, we specialize in building custom phototransistor setups that solve those exact headaches.

Phototransistors are basically light-sensitive transistors, great for turning light into electrical signals with some built-in amplification. Silicon ones, like the kind we use, typically peak around 840-850 nm in the near-infrared, which makes them awesome for pairing with IR LEDs. But stock versions often come with fixed windows and pinouts that don’t always match what you need.

Why Go for a Custom Phototransistor?

Standard parts are fine for simple stuff, but when your project demands specific spectral response or mechanical fit, customization changes everything. Think about it: a one-size-fits-all approach works for t-shirts, but not always for sensors in real-world gear.

We’ve helped folks in automation, medical devices, and consumer electronics get exactly what they need. For instance, one client was building an industrial counter that had to ignore ambient visible light – a filtered window made all the difference. Another needed super-compact SMD pins for a tight PCB. These aren’t made-up stories; they’re the kind of tweaks we’ve done over years of working with silicon phototransistors.

Customization lets you dial in performance. Whether it’s a customized optical sensor for precise detection or an OEM light sensor integrated into your product line, it boosts reliability and cuts down on extra components.

Understanding Window Materials in Phototransistors

The “window” is that transparent part on top – usually a lens-shaped cover that lets light hit the silicon chip. It doesn’t just protect; it shapes how the sensor responds to different wavelengths.

Common materials include:

- Epoxy resin: Cheap and common in plastic packages. It’s clear for visible and near-IR, but can yellow over time or let in too much unwanted light.

- Glass: More durable, better for high-temps or harsh environments. Often used in metal cans like TO-18.

- Special plastics or coated resins: These can filter specific bands.

The material affects spectral responsivity big time. Silicon phototransistors naturally respond from about 400 nm (visible blue) up to 1100 nm (near-IR), peaking in the 800-900 nm range. But if your app is IR-only, like remote controls or proximity sensing, you don’t want visible light messing things up.

How Window Materials Influence Spectral Response

Clear epoxy lets everything through – great for broad-spectrum stuff, but noisy in bright rooms.

Tinted or filtered windows block visible light, shifting focus to IR. Some add day-light filters (like black epoxy) that cut off below 700-800 nm.

Coatings can flatten response or enhance certain bands. For example, many commercial ones use resin that acts as a high-pass filter for IR.

Here’s a quick comparison table to make it clearer:

| Window Material | Typical Transmission | Pros | Cons | Best For |

|---|---|---|---|---|

| Clear Epoxy Resin | Broad: 400-1100 nm | Low cost, easy molding with lens | Sensitive to visible light, ages faster | General purpose, indoor low-light |

| Tinted/Black Epoxy | 700-1100 nm (IR focus) | Blocks visible/ambient interference | Reduced overall sensitivity | Outdoor or bright environments, proximity sensors |

| Glass (uncoated) | High transmission 350-2000 nm | Durable, stable over time/temp | No built-in filtering | High-reliability apps, wide spectrum |

| Coated Resin/Plastic | Customizable (e.g., visible block or IR pass) | Tailored response, anti-reflective options | Higher cost | Precise spectral needs, medical or analytical |

We’ve used tinted epoxy in a bunch of projects to make sensors ignore room lights – one case was a punch-card reader that worked flawlessly under fluorescent bulbs after switching windows.

Pin Options and Package Configurations

Pins might seem boring, but wrong ones mean redesigning your whole board. Common packages for phototransistors:

- TO-18 or TO-46 metal cans: 3-pin (sometimes base accessible), hermetic, great for rugged stuff.

- TO-92 plastic: Through-hole, cheap, 3-pin but pinout varies (watch for EBC vs CBE).

- SMD (like SOT-23 or mini-flat): Surface mount, compact, top or side view.

Pin count is usually 2 (emitter and collector, base floating) or 3 (with base for extra control).

Customizing pins means choosing package, orientation, or even lead forming.

Popular Pin/Package Options Table

| Package Type | Pin Count | Mounting | Typical Use | Customization Notes |

|---|---|---|---|---|

| TO-18 Metal Can | 3 | Through-hole | High reliability, narrow angle | Hermetic seal, radiation tolerant options |

| TO-92 Plastic | 2-3 | Through-hole | Hobby/prototyping | Easy to bend leads, various pinouts |

| SMD (e.g., 5mm or flat) | 2-4 | Surface mount | Compact devices | Dome lens for focus, side-lookers available |

| Custom Array | Multiple | Varies | Multi-channel sensing | Monolithic arrays for position detection |

In one project, a client switched to SMD pins for a wearable device – saved space and made assembly easier.

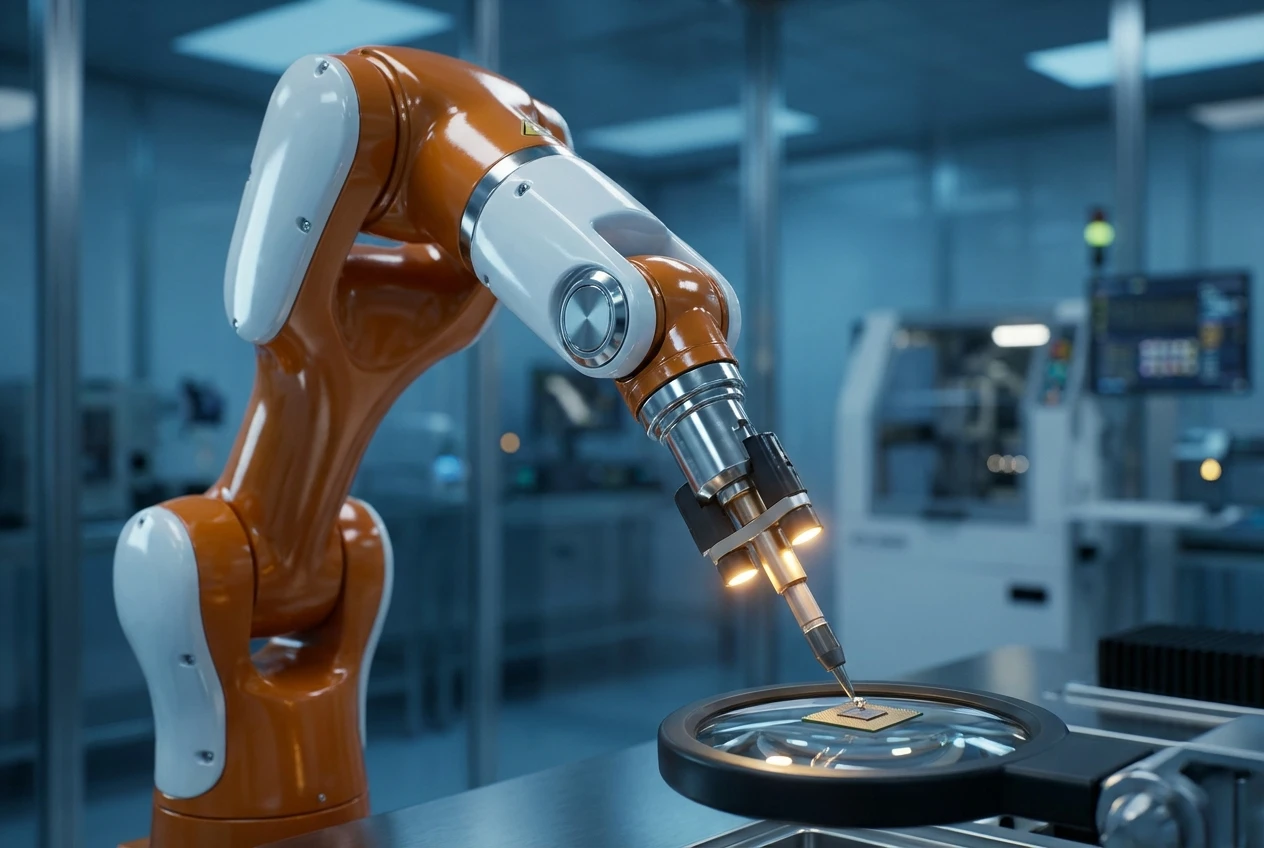

Real-World Applications and Examples

Phototransistors pop up everywhere: position sensing (like in printers for paper detection), opto-isolators for safety, coin counters, smoke detectors (though often with IR), remote controls, and even encoders.

We had a customer building automated sorting machines – they needed a customized optical sensor with IR-filtered window and specific pins to fit their conveyor setup. After tweaking the epoxy to block visible and going with TO-92 pins, detection accuracy jumped, false triggers dropped.

Another anonymous case: a medical equipment maker wanted low-noise OEM light sensors for pulse monitoring. Custom glass window for stability, 2-pin config – worked reliably in varying lights.

These tweaks aren’t fancy; they just make things work better.

Benefits of Customization with Bee Photon

At Bee Photon, we’ve got years handling silicon phototransistors. We offer full customization: pick window material for your spectrum, pins for your board, even die-level tweaks if volumes justify.

No huge MOQs for starters – we do prototypes to production.

Plus, our stuff is reliable; silicon tech is mature, and we back it with testing.

FAQ

What’s the difference between a standard and custom phototransistor?

Standards are fixed; customs let you change window filtering, package, pins, even response curve. Great when off-shelf doesn’t cut it.

How does window material affect performance?

It filters wavelengths. Clear for broad, tinted for IR-only – reduces noise from ambient light.

Can I get a customized optical sensor for visible light blocking?

Yeah, absolutely. We often use day-light filters or black epoxy for that.

What pin options are available for OEM light sensors?

From classic TO-18 through-hole to modern SMD – whatever fits your design.

Ready to tweak a phototransistor for your setup? Drop us a line at info@photo-detector.com or head to our contact page. We can chat specs, quotes, samples – no pressure, just helpful info.