Look, I’ve been around the automation block a few times. If you are building Automated Optical Inspection (AOI) equipment, you know the nightmare. Your machine is running, the PCBs are flying by on the conveyor, and suddenly—stop. False reject. Again.

The camera thought a shadow was a crack. Or maybe the lighting flickered, and your sensor missed a bridge defect on a microcontroller. It’s frustrating.

Most people just throw better software or higher-resolution cameras at the problem. But honestly? That’s often looking at the wrong end of the horse. The real bottleneck is usually the raw speed and sensitivity of the physical sensing element.

This is where machine vision photodiodes come into play, specifically the Silicon (Si) PIN variety. I’m not talking about generic light sensors you buy for five cents. I’m talking about the industrial-grade stuff we deal with at BeePhoton.

Today, I want to walk you through why switching to Si PIN solutions might just be the upgrade your PCB inspection gear needs. I’ll keep the heavy math to a minimum, but we need to talk a bit of physics to understand why these things are so fast.

The Problem with Standard Cameras in High-Speed AOI

We all love a good CMOS camera. They are great for taking a pretty picture of the whole board. But when you are hunting for microscopic defects on a line moving at 2 meters per second, frame rates become a killer.

Even a global shutter camera has a “readout” time. While the camera is processing the data from the last frame, your PCB has moved.

Photodiodes don’t have frames. They offer a continuous analog output that correlates instantly to light intensity. When you use them for laser triangulation or spot checking specific components, the response time is measured in nanoseconds, not milliseconds.

In the world of PCB inspection sensors, that difference is everything.

Why Si PIN Photodiodes Are the AOI Sweet Spot

So, why specifically Si PIN? Why not APDs (Avalanche Photodiodes) or standard phototransistors?

Here is the deal.

- Speed: Phototransistors are slow. They have high gain, but they are sluggish. Si PIN diodes utilize an intrinsic layer (that’s the ‘I’ in PIN) that reduces the junction capacitance. Lower capacitance = higher speed.

- Linearität: In automated optical inspection (AOI), you need to know exactly how much light is bouncing back from that solder joint. Si PIN diodes are incredibly linear. If you double the light, you double the current. No guessing games.

- Cost vs. Performance: APDs are faster but require high voltage and are noisy as heck if you don’t control the temperature. Si PINs are the workhorse—stable, fast, and affordable.

I remember helping a client last year who was building a machine to check the leg straightness on TQFP chips. Their camera setup kept blurring the edges. We swapped the trigger mechanism to a laser/photodiode pair using one of our high-speed Si-PIN-Fotodioden, and they increased their line speed by 40% without losing accuracy.

Si-PIN-Fotodiode Serie PDCP08 PDCP08-502

Die PDCP08-502 ist eine 2,9×2,8 mm große Silizium-PIN-Photodiode mit hohem Ansprechverhalten, die für fotoelektrische Präzisionsanwendungen entwickelt wurde. Mit niedriger Sperrschichtkapazität, niedrigem Dunkelstrom und einem breiten Spektralbereich (340-1100 nm) ist sie das ideale Bauteil für optische Schalter und kompakte Sensormodule, die eine stabile und schnelle Signalausgabe erfordern.

The Technical Nitty-Gritty: Understanding the Specs

Okay, let’s get a little technical. If you are an engineer sourcing parts for your next build, you can’t just pick any diode. You need to look at the Rise Time und Spectral Response.

Rise Time and Bandwidth

The bandwidth (BW) of your system is directly tied to the rise time (tr) of the photodiode. The rough formula you can plug into your notes is:

BW = 0.35 / tr

If your photodiode has a rise time of 10 nanoseconds (ns), your bandwidth is roughly 35 MHz.

Why does this matter? If your laser is scanning across a PCB trace that is only 0.1mm wide, and the board is moving fast, the “pulse” of light reflected back to the sensor is incredibly short. If your sensor is too slow, that pulse turns into a blob, and you miss the defect.

Unter BeePhoton, we often see engineers ignoring the capacitance. The junction capacitance (Cj) combined with your load resistance (RL) creates a low-pass filter.

tr = 2.2 * R_load * Cj

(Note: This is a simplified approximation, but it holds up for most basic designs).

If you want speed, you need low capacitance. And you need to keep your load resistance low, although that drops your voltage signal. It’s a balancing act.

Spectral Response: Matching the Laser

Most AOI systems use red lasers (around 650nm) or Near-Infrared (NIR) at 850nm or 940nm. Silicon is naturally great at detecting these wavelengths.

However, if you are inspecting special coatings on PCBs, you might be using UV light to check for conformal coating presence. Standard Si detectors drop off in sensitivity around the UV range. You need enhanced UV-sensitive diodes for that.

I’ve seen guys try to use standard IR-filtered sensors for UV applications and wonder why they get zero signal. Don’t be that guy. match the peak sensitivity of the diode to your light source.

Integrating BeePhoton Sensors: A Practical Guide

When you grab a sensor from our Si-PIN-Fotodioden catalog, you aren’t just getting a component; you’re getting a precision instrument. But you have to treat it right.

The Transimpedance Amplifier (TIA)

You cannot just hook a photodiode up to a multimeter. You need a TIA circuit to convert that tiny current (Photocurrent) into a usable Voltage.

The basic output voltage (Vout) is:

Vout = I_pd * Rf

Wo:

I_pdis the photocurrent generated by the light.Rfis the feedback resistor.

Here is a tip from the trenches: Keep the traces between the photodiode and the operational amplifier (Op-Amp) as short as physically possible. I mean millimeters. Long traces act like antennas. In a factory full of motors and EMI, long traces will pick up noise that looks exactly like a scratch on a PCB.

Shielding is Not Optional

In automated optical inspection (AOI) environments, electrical noise is everywhere. If you are designing a custom head for your machine, enclose the photodiode and the amp in a metal shield. Ground the shield. It sounds basic, but 50% of the “defective sensor” calls we get at info@photo-detector.com turn out to be grounding issues.

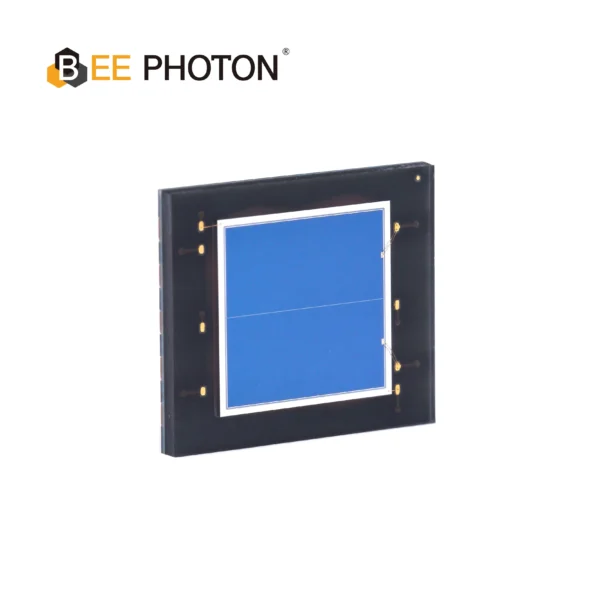

Si-PIN-Photodioden-Array Doppel-PD PDCA02-103

Die PDCA02-103 ist eine leistungsstarke Photodioden-Array für die Datenübertragung, mit einem robusten Dual-Element-Design. Mit einer großen lichtempfindlichen Fläche von 10×5 mm pro Element und einem kompakten Gehäuse von 16,5×14,5 mm gewährleistet diese Silizium-PIN-Photodiode eine außergewöhnliche Signalstabilität und Ausrichtungstoleranz für fortschrittliche optische Kommunikationssysteme.

Case Study: The “Phantom” Solder Bridge

Let me share a quick story (names changed to protect the NDA, obviously).

A manufacturer of automotive ECUs came to us. They were using a vision system to detect solder bridges between pins. The problem? The shiny solder mask on the PCB was reflecting light in a way that confused their camera software. It looked like a bridge, but it wasn’t.

Their false reject rate was 8%. That is huge in automotive.

They decided to add a secondary check: a high-speed laser sweep using machine vision photodiodes.

We recommended a specific Si PIN detector with a narrow viewing angle to block out stray light.

Das Ergebnis:

- They set the threshold so that only the high intensity of a direct metal reflection (the solder bridge) would trigger the sensor. The glossy PCB mask reflection was too weak to trigger it.

- False rejects dropped to under 0.5%.

- ROI was achieved in about two months just by saving manual rework labor.

This is why specialized hardware beats generic software fixes.

Comparison: Si PIN vs. The Rest

To make it easier for you to decide, I threw together this table. It compares the common sensor types used in AOI.

| Merkmal | Si-PIN-Fotodiode | Fototransistor | CCD/CMOS Camera | Avalanche-Photodiode (APD) |

|---|---|---|---|---|

| Speed (Response Time) | Very Fast (ns) | Slow (µs) | Slow (Frame based) | Extremely Fast (ps/ns) |

| Gain | 1 (Unity) | Hoch | K.A. | High (Internal gain) |

| Circuit Complexity | Low/Medium | Niedrig | Hoch | High (Needs HV) |

| Kosten | Niedrig | Sehr niedrig | Hoch | Hoch |

| Am besten für | High-speed counting, edge detection, laser triangulation | Basic presence sensing | Visual pattern recognition | Low-light, high-speed telecom |

You can see why Si PIN is the sweet spot for PCB inspection sensors. It gives you the speed of an APD without the high cost and complex circuitry.

Common Pitfalls in AOI Sensor Selection

I want to save you some headache. Here are things I see people mess up all the time.

- Ignoring Dark Current: Every photodiode generates a tiny bit of current even in pitch blackness. This is “Dark Current.” If you are trying to detect very faint defects, high dark current will bury your signal. Check the datasheet.

- Temperature Drift: Silicon changes behavior when it gets hot. If your AOI machine is inside a hot enclosure, the sensitivity might shift. You might need a sensor with better thermal stability or add a temperature compensation circuit.

- Field of View: A photodiode sees everything in front of it. If you don’t use a lens or an aperture (a tiny hole), it will see the defect und the background. You need optical control to focus the sensor on exactly the spot you want to inspect.

Si-PIN-Photodiode mit erhöhter UV-Empfindlichkeit (190-1100nm) PDCT06-F01

Erzielen Sie eine schnelle Signalerfassung mit unserer Si-PIN-Photodiode mit schneller Anstiegszeit. Optimiert für optische Kommunikation und Impulserkennung mit niedriger Kapazität und hoher Zuverlässigkeit. Nutzen Sie noch heute die Leistung einer schnellen Si-PIN-Photodiode.

Why Partner with BeePhoton?

There are a million places to buy electronic components. Why come to BeePhoton?

Because we don’t just ship bags of parts. We understand the optics. When you are trying to figure out if you need a TO-can package or a surface mount chip, or if you need an integrated filter to block out ambient factory light, we can actually answer those questions.

Unser Si-PIN-Fotodioden are manufactured with strict quality controls because we know they are going into machines that run 24/7.

We have helped dozens of equipment manufacturers fine-tune their optical decks. We know that in B2B, a stopped line costs thousands of dollars a minute. You need reliability.

Final Thoughts on Upgrading Your Line

If your AOI system is hitting a wall, stop blaming the code. Look at the eyes of the machine.

Are they fast enough? Are they linear? Are they seeing what they need to see?

Switching to high-performance machine vision photodiodes is often the most cost-effective way to boost throughput and accuracy simultaneously. It’s not magic; it’s just better physics.

Do not let outdated sensor tech hold your production back.

FAQ: Machine Vision Sensors

Q: Can I replace a camera with a photodiode in my AOI system?

A: Not entirely. Cameras are best for pattern matching (like reading a QR code or checking if a part is rotated). Photodiodes are best for high-speed triggering, edge detection, and laser triangulation. They work best together as a hybrid system.

Q: What is the main advantage of Si PIN over standard phototransistors for PCBs?

A: Speed and Linearity. Phototransistors saturate easily and are too slow for modern high-speed conveyor lines. Si PIN diodes respond instantly to light changes, allowing for faster scanning speeds.

Q: Do I need a custom circuit for BeePhoton sensors?

A: It depends. We offer both raw components and sensors with integrated pre-amplifiers. If you are building from scratch, you will need a Transimpedance Amplifier (TIA) circuit. If you contact us, we can share some reference designs to get you started.

Ready to boost your inspection speed?

Don’t let microscopic defects slip through the cracks. If you are unsure which sensor fits your specific machine architecture, let’s talk.

- Check out our full range here: Si PIN Photodiodes Catalog

- Need a custom solution? Drop us a line at Kontakt

- Email our engineering team directly: info@photo-detector.com

Upgrade your vision today with BeePhoton.