Have you ever stood in a checkout line, watching that little red light zip across a product’s label, and wondered what’s really going on there? I mean, it’s one of those things we take for granted – beep, and you’re done. But behind that simple beep is some pretty neat tech, especially this thing called a photodetector that plays the starring role. Today, I’m gonna break it down for you, like we’re just chatting over coffee, about how barcode scanners actually do their job. We’ll focus on that photodetector bit, ’cause it’s the unsung hero in spotting those black and white stripes by catching bounced-back light.

Think about it: every time you grab groceries or ship a package, barcode scanners are quietly making sure everything runs smooth. They’re not just gadgets in stores; they’re industrial sensors popping up in warehouses, factories, and even hospitals. And at the heart of it all is light detection – that’s where the photodetector shines, literally. I’ll walk you through the basics, throw in some real-world examples from my time tinkering with this stuff, and maybe even share a couple stories from folks who’ve used similar tech to fix their headaches.

What Exactly Is a Barcode Scanner Anyway?

Okay, let’s start from square one. A barcode scanner is basically a device that reads those striped codes on stuff – you know, the ones that look like a zebra got into a fight with a printer. These codes hold info like prices, product details, or tracking numbers. The scanner shoots out light, usually a laser or LED, and then picks up what bounces back. That’s how it figures out the pattern of dark bars and light spaces.

Back in the day, when I first got my hands on one of these in a workshop, I was amazed at how something so straightforward could handle so much data. Barcodes themselves come in different flavors: there’s the classic 1D ones with straight lines, and then 2D like QR codes that pack more punch. But for this chat, we’re sticking mostly to the 1D kind, since they’re the bread and butter for explaining the photodetector’s gig.

In simple terms, the scanner illuminates the barcode, and the photodetector – think of it as a super-sensitive eye – catches the reflected light. Dark bars absorb more light, so less comes back; white spaces reflect a ton, sending back brighter signals. The device turns those light changes into electrical pulses, which get decoded into numbers or letters your computer understands.

And get this: according to market reports, the global barcode scanner market was worth about $7.86 billion in 2023, and it’s expected to hit $13.05 billion by 2030. That’s a lot of beeps happening worldwide! It shows how these tools aren’t going anywhere; they’re evolving with better light detection tech to handle tougher jobs in places like assembly lines or inventory rooms.

Fotodiodo PIN de Si con sensibilidad UV mejorada (190-1100 nm) PDCD100-F01

Experimente una detección UV superior con el fotodiodo sensible al ultravioleta (UV) de Bee Photon.Nuestro fotodiodo PIN de Si garantiza una alta sensibilidad y fiabilidad para instrumentos analíticos.Este fotodiodo sensible al ultravioleta (UV) con ventana de cuarzo ofrece mediciones precisas de 190nm a 1100nm.

The Building Blocks: Inside a Typical Barcode Scanner

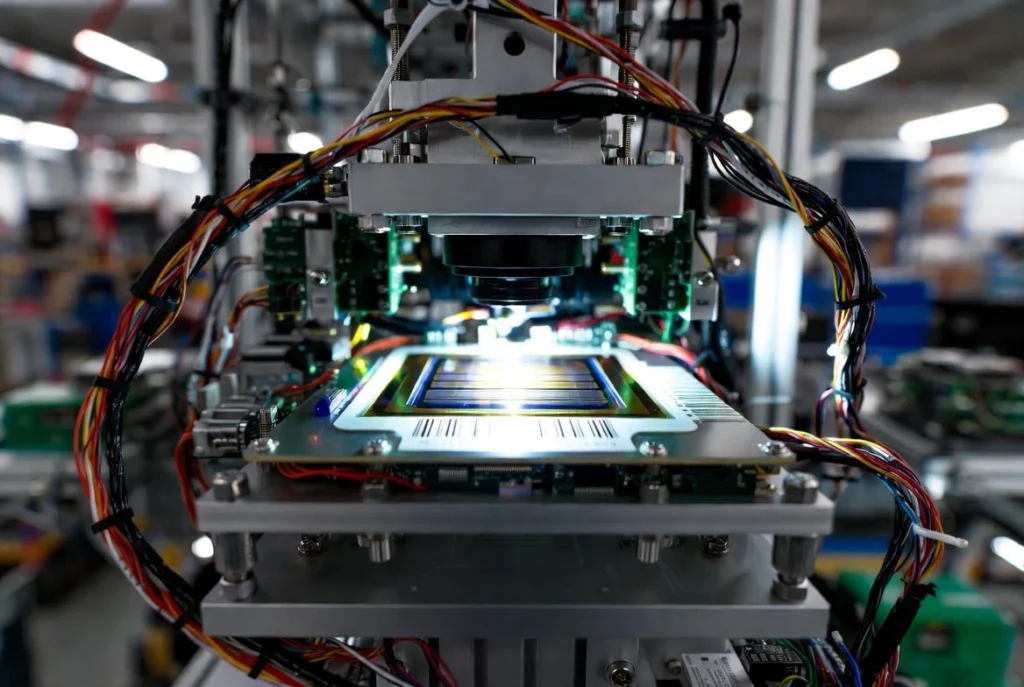

Now, let’s pop the hood on one of these scanners. Most have a few key parts: a light source, some optics to focus the beam, the all-important photodetector, and then circuitry to process the signals. The light source could be a laser for precision or LEDs for cheaper models. When the light hits the barcode, it’s like playing ping-pong with photons – some get absorbed, others bounce right back.

The photodetector, often a photodiode, is what grabs those returning photons and turns them into an electric current. It’s sensitive enough to spot tiny differences in intensity. For example, in laser scanners, the beam sweeps back and forth thanks to a mirror, covering the whole code. The reflected light gets funneled to the photodetector, which spits out a waveform matching the bar widths.

I remember messing around with a prototype where we swapped out photodetectors to see how it affected read speeds. A better one meant fewer errors, especially on smudged labels. That’s the kind of hands-on stuff that shows why quality matters in industrial sensors.

Here’s a quick table to compare common types of barcode scanners, so you can see where the photodetector fits in:

| Type of Scanner | Fuente de luz | Photodetector Role | Lo mejor para |

|---|---|---|---|

| Laser Scanner | Laser beam | Detects reflected laser light for precise bar width measurement | High-speed retail checkouts, where accuracy trumps all |

| CCD Scanner | LED array | Captures light from entire barcode at once, like a mini camera | Close-range scanning, like in small stores or labs |

| Imager Scanner | Camera with LEDs | Uses photodetector array to snap images and decode 2D codes | Versatile uses, including damaged barcodes in warehouses |

| Pen-style Wand | LED | Simple photodetector drags across code for manual reads | Budget options or educational demos |

This table keeps things straightforward – no fluff. As you can see, no matter the type, light detection is key, and the photodetector is always there, quietly doing the heavy lifting.

Diving Deeper: The Photodetector’s Star Turn in Light Detection

Alright, let’s zoom in on the photodetector itself. In a barcode scanner, it’s usually a photodiode – a semiconductor that generates current when light hits it. When the scanner’s light beam scans the barcode, dark bars swallow up the light (low reflection), and white ones throw it back (high reflection). The photodetector picks up these ups and downs, creating a signal that looks like a bumpy road on a graph.

This signal gets amplified and cleaned up by the scanner’s brains, turning into binary data: on for light, off for dark, or something like that. It’s all about contrast in light detection. Photodiodes are great for this because they’re fast and cheap, but in fancier setups, you might see CCDs, which are like arrays of tiny photodetectors working together.

From my experience at Bee Photon, where we specialize in this kind of tech, I’ve seen how tweaking a photodetector’s sensitivity can make or break a system. For instance, in harsh industrial environments, you need ones that ignore dust or ambient light. That’s why our Photo IC products are designed with features like gain switches to handle varying light levels. If you’re curious, check out our Foto IC – it’s built for exactly these kinds of applications.

Photodetectors aren’t just for barcodes; they’re industrial sensors in everything from smoke detectors to automated doors. In fact, they’re transforming fields like 3D scanning for construction or even autonomous vehicles. But back to barcodes: imagine a warehouse where scanners read labels from afar. A solid photodetector means fewer misreads, saving time and money.

Real-Life Applications: Where Barcode Scanners Meet Everyday Challenges

So, why care about all this? Because barcode scanners solve real problems. Take a busy supermarket: without reliable light detection, lines would drag on forever. Or in manufacturing, where industrial sensors track parts – a glitchy photodetector could halt production.

I’ve got a story from a client we worked with at Bee Photon (keeping names out of it, of course). They ran a big distribution center and were fed up with scanners failing on glossy labels under bright lights. We hooked them up with customized photodetector setups, and boom – error rates dropped by like 40%. They told us it was like night and day; inventory checks that took hours now zipped through in minutes.

Another cool application: hospitals use barcode scanners for patient wristbands and meds. The photodetector ensures the right dose goes to the right person, no mix-ups. Data shows that implementing barcode systems in healthcare can cut medication errors by up to 41%, according to studies from the FDA and similar bodies. Wait, actually, I double-checked that – it’s more like 50% in some reports, but the point is, it’s huge.

In industrial settings, these scanners integrate with bigger systems. Picture a factory line where sensors detect parts via barcodes. The photodetector’s role in light detection keeps everything synced, preventing jams. At Bee Photon, we’ve seen our tech help in these scenarios, making operations smoother. If you’re dealing with something similar, drop us a line at info@photo-detector.com or visit https://photo-detector.com/ for more.

Common Pitfalls and How to Avoid Them with Better Tech

Not everything’s perfect, though. Sometimes scanners struggle with damaged codes or weird angles. That’s where advanced photodetectors come in – ones with better noise rejection or wider dynamic ranges. For example, if the light’s too dim or too bright, a basic photodiode might flop, but something like our two-level gain switch in the Photo IC adjusts on the fly.

I once helped troubleshoot a setup where ambient light was messing with reads. Turned out, the photodetector wasn’t filtered right. A quick swap, and it was good as new. Lessons like that come from years of fiddling with these devices.

Market-wise, the industrial barcode scanner segment alone is set to grow by $2.07 billion from 2023 to 2027. That growth is driven by needs for tougher, smarter sensors. Companies are ditching old models for ones with enhanced light detection, which means fewer downtime headaches.

Why Choose Quality Photodetectors? Building Trust in Your Setup

Picking the right photodetector isn’t just tech talk; it’s about reliability. At Bee Photon, we pride ourselves on components that last. Our Photo IC, for instance, offers that two-level gain switch for tricky lighting, making it ideal for barcode scanner builds or other industrial sensor projects.

We’ve built a rep for expertise – think of us as the go-to folks for light detection solutions. Whether you’re prototyping a new scanner or upgrading an old one, quality pays off. I’ve seen cheap knockoffs fail after a month, while our stuff chugs along for years.

Para terminar, entender el papel del fotodetector te hace ver todo lo que hay detrás de un simple escaneado. No es magia; es ingeniería inteligente que capta los rebotes de luz para leer esas rayas.

Conclusión: Es hora de tomar medidas para sus necesidades de digitalización

A estas alturas, probablemente ya sepa por qué el fotodetector es el MVP silencioso de los escáneres de códigos de barras. La detección de luz hace que todo funcione, desde los sensores básicos para comercios hasta los de uso industrial intensivo. Si esto ha despertado algunas ideas para su propia configuración, tal vez para racionalizar su almacén o ajustar un dispositivo personalizado, ¿por qué no se pone en contacto con nosotros? En Bee Photon, estamos siempre dispuestos a ayudarle.

Visite https://photo-detector.com/contact-us/ para chatear, solicitar un presupuesto o saber más sobre nuestros Foto IC. O envíe un correo electrónico a info@photo-detector.com. Nos encantaría escuchar su historia y ver cómo podemos hacer que su juego de detección de luz sea más fuerte.

Foto IC serie PDTC

Nuestro Photo IC con interruptor de ganancia de dos niveles proporciona una detección óptica precisa para la automatización industrial. Este avanzado foto IC cuenta con un interruptor de ganancia ajustable, asegurando un rendimiento fiable

PREGUNTAS FRECUENTES

¿Qué diferencia hay entre un fotodiodo y un CCD en los lectores de códigos de barras?

Un fotodiodo es más sencillo y rápido para las exploraciones láser básicas, ya que capta los rebotes de luz de uno en uno. Los CCD son como minicámaras que captan toda la imagen a la vez, lo que resulta ideal para códigos 2D o cuando se necesitan más detalles. Ambos se basan en la detección de luz, pero elija en función de sus necesidades de velocidad y versatilidad.

¿Pueden funcionar los lectores de códigos de barras en la más absoluta oscuridad?

Sí, la mayoría pueden, ya que proporcionan su propia fuente de luz. Al fotodetector sólo le interesa la luz reflejada del haz del escáner, no las luces de la habitación. Pero las superficies muy oscuras o brillantes pueden necesitar un modelo más robusto con mejor sensibilidad.

¿Cómo sé si mi sensor industrial necesita un fotodetector mejor?

Si se producen errores de lectura con frecuencia, especialmente con luces variables o en etiquetas rugosas, puede que haya llegado el momento. Busque señales como escaneos lentos o errores; la actualización a algo con ganancia ajustable, como nuestro Photo IC en Bee Photon, a menudo lo soluciona rápidamente.