You know how smartwatches and those slick AR/VR glasses keep getting thinner and lighter every year? Yeah, the real magic happens under the hood with tiny components that have to squeeze into super small spaces without losing performance. That’s where miniaturized photodiodes come in. They’ve become a game changer for anyone building the next wave of wearables.

At Bee Photon, we’ve been deep in this space for years, helping smartwatch and AR/VR glasses makers pack more functionality into less space. Today I wanna walk you through why these little guys matter so much, what makes them tick, and how they actually solve the headaches you’re probably dealing with right now – like fitting accurate health monitoring tech into a tiny wristband or slim glasses frame.

Why Size Matters More Than Ever in Wearables

Let’s be honest: consumers want devices that feel almost invisible. Smartwatches can’t be chunky bricks anymore, and AR/VR glasses? They gotta look like regular eyewear, not sci-fi gear.

The global wearable sensors market is exploding – estimates put it around USD 1.5-1.9 billion in 2025, with some projections saying it’ll hit USD 5-13 billion by 2034, growing at 15-21% CAGR depending on the source. Health monitoring features like heart rate, SpO2, and even stress tracking drive a lot of that demand.

But here’s the catch: to make those measurements accurate, you need photodiodes that can detect light reliably – green for heart rate, red/IR for oxygen levels. Traditional photodiodes used to take up way too much room. Now, with chip-scale package tech, we’re talking devices as small as 2.0 mm x 1.8 mm x 0.6 mm (like some commercial PIN photodiodes out there). That frees up precious real estate for batteries, processors, or more sensors.

For smartwatch makers, this means sleeker designs without sacrificing signal quality. For AR/VR glasses manufacturers, it opens doors to better eye-tracking or ambient light adjustment in ultra-thin frames.

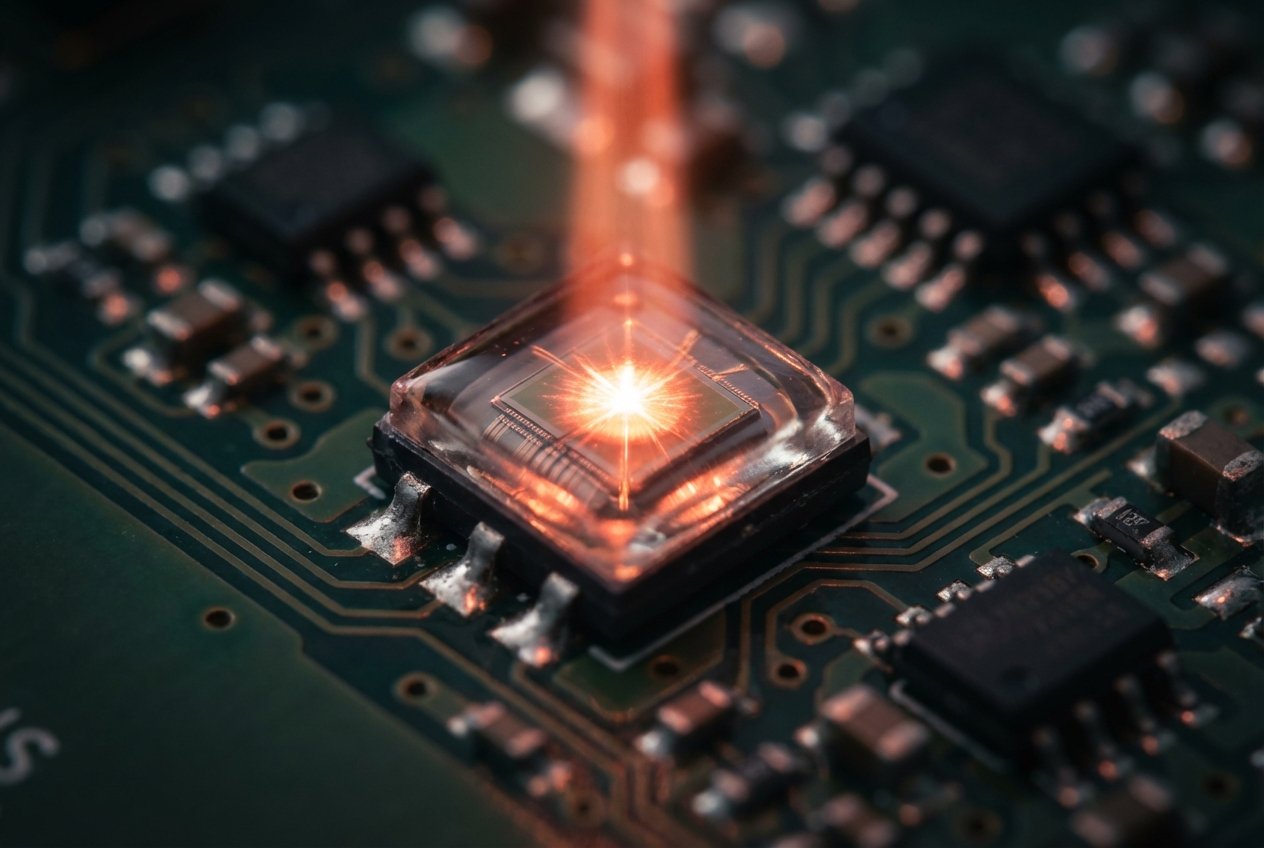

Si PIN photodiode PDCP08 Series PDCP08-511

The PDCP08-511 is a high-performance Black Epoxy PIN Photodiode designed for precision infrared applications. Encased in a special black epoxy resin, this sensor effectively acts as a daylight filter, blocking visible light interference while maximizing sensitivity at 940nm. With a large 2.9×2.9mm active area and low dark current, it ensures reliable signal detection for optical switches and remote control systems, even in noisy ambient light environments.

The Tech Behind Miniaturized Photodiodes

So what exactly makes these photodiodes “miniaturized” and ready for next-gen wearables?

First off, chip-scale package (CSP) shrinks the whole thing down close to the die size itself. No bulky leads or extra housing – just a tiny footprint with direct mounting. We’ve seen commercial examples hitting areas under 4 mm² while still delivering fast response times (around 70 ns) and low capacitance (like 17-18 pF).

These specs matter because in PPG (photoplethysmography) – the tech behind most wrist-based heart rate and SpO2 – you need quick, low-noise detection of tiny light changes from blood flow.

Some key advantages we’ve worked with:

- High sensitivity across visible and near-IR (350-1100 nm)

- Low dark current to cut noise in dim conditions

- Fast switching for real-time data

And yeah, power consumption stays low, which is huge when your device runs all day on a small battery.

Comparison of Photodiode Packages for Wearables

Here’s a quick table comparing traditional vs modern miniaturized options (based on real commercial examples):

| Feature | Traditional SMD Package | Chip-Scale Package (Modern Miniaturized) | Benefit for Wearables |

|---|---|---|---|

| Typical Size | 3-5 mm side | 1.8-2.5 mm side | 50-70% smaller footprint |

| Height | 1-2 mm | 0.5-0.7 mm | Thinner devices |

| Sensitive Area | ~2-4 mm² | 1.5-6 mm² (optimized) | Better light collection in small space |

| Response Time | 100+ ns | ~70 ns | Faster PPG sampling |

| Capacitance | 20-50 pF | 17-20 pF | Less noise, cleaner signals |

| Power Draw (typical) | Higher | Ultra-low | Longer battery life |

As you can see, the jump to CSP makes a big difference when you’re cramming everything into a 10-15 mm module.

How Miniaturized Photodiodes Power Health Monitoring Tech

Most wearables use PPG for health monitoring tech. Green LEDs shine light into your skin, and the photodiode picks up the reflected signal that changes with each heartbeat.

In real projects we’ve supported (anonymized of course), a manufacturer switched to our miniaturized photodiodes in chip-scale package for their flagship smartwatch line. They managed to:

- Reduce the optical module size by ~40%

- Improve heart rate accuracy during workouts (less motion artifact thanks to better signal-to-noise)

- Add SpO2 without making the watch thicker

For AR/VR glasses, photodiodes help with ambient light sensing, proximity detection, or even basic eye-tracking setups. The tiny size lets designers hide sensors along the frame without ugly bulges.

One cool application we’ve seen is multi-channel setups – multiple photodiodes for better spatial resolution in PPG, catching subtle changes across the wrist or temple area.

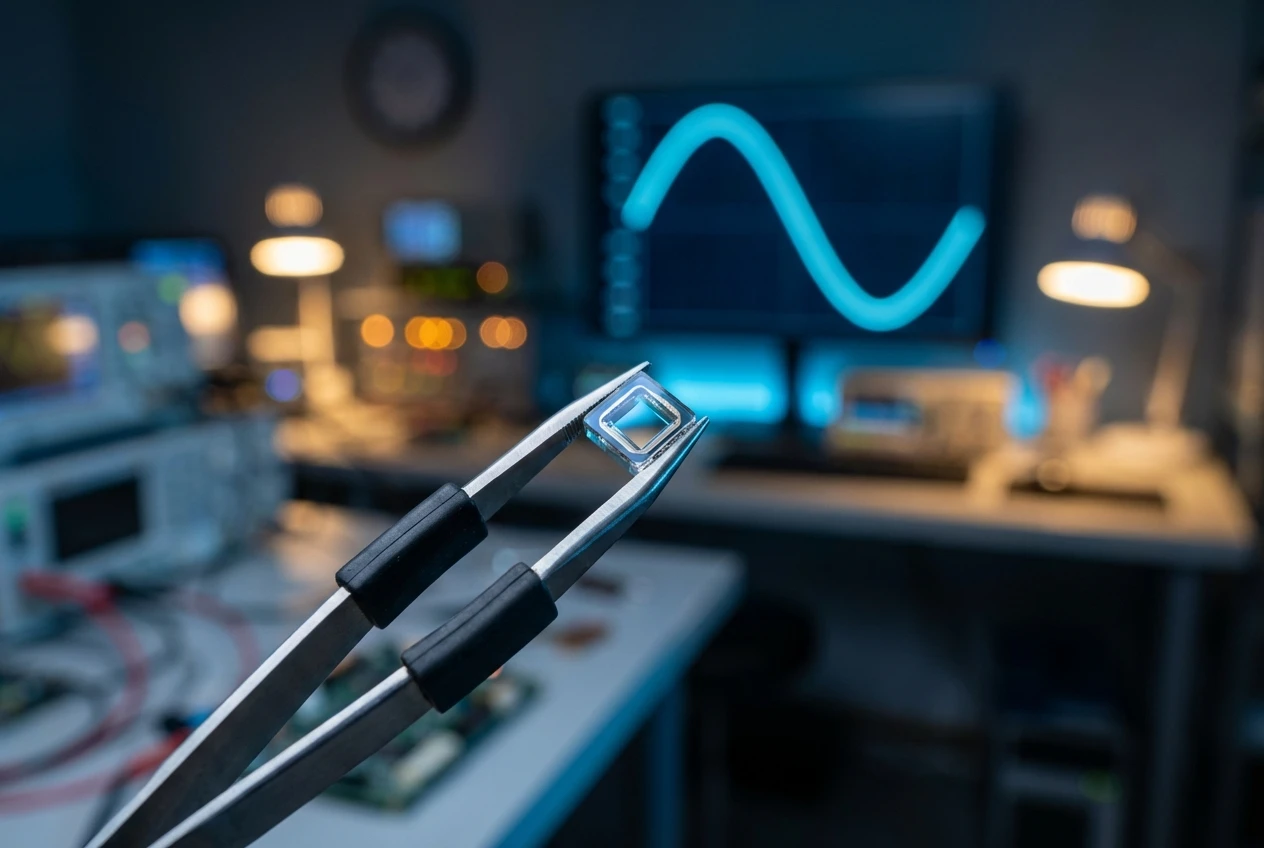

Si PIN photodiode PDCP08 Series PDCP08-501

High-Performance Detection: The PDCP08-501 is a high-speed Silicon PIN Photodiode with a transparent window.

Key Specs: Featuring a 2.9×2.9mm active area, this PIN photodiode offers low dark current and high responsivity, making it an ideal sensor for general optical switches and light detection systems.

Challenges We’ve Actually Faced (and Solved)

It’s not all smooth sailing. Motion artifacts can wreck PPG signals, skin tones affect light absorption, and power budgets are tight.

But miniaturized designs help here too. Lower capacitance means quicker response to changes, and higher sensitivity cuts the LED power needed. We’ve tested prototypes where switching to CSP photodiodes dropped overall module power by 15-20% while keeping (or improving) accuracy.

For AR/VR, thermal management gets tricky in tiny glasses – these low-power photodiodes generate almost no heat, which helps.

Real-World Success Stories (Keeping It Real)

I can’t name names, but one client building high-end smartwatches told us their returns dropped noticeably after integrating smaller, more reliable photodiodes – fewer complaints about inconsistent heart rate readings. Another AR glasses project squeezed in extra ambient sensors without redesigning the frame, hitting their weight target.

These aren’t hypotheticals; they’re the kinds of wins that come from focusing on size without compromising performance.

What to Look for When Choosing Your Next Photodiode Supplier

If you’re in R&D for smartwatches or AR/VR glasses, here’s what actually matters:

- Footprint under 2.5 x 2.5 mm

- CSP or WLCSP packaging

- Proven PPG performance (check datasheets for reverse light current)

- Customization options for wavelength range

And don’t forget supply chain reliability – nothing worse than delays when you’re racing to launch.

Si PIN photodiode PDCP08 Series PDCP08-502

The PDCP08-502 is a high-response 2.9×2.8mm Silicon PIN Photodiode designed for precision photoelectric applications. Featuring low junction capacitance, low dark current, and a wide spectral range (340-1100nm), it is the ideal component for optical switches and compact sensing modules requiring stable and fast signal output.

Ready to Shrink Your Design?

Look, if you’re tired of compromises between size, performance, and battery life, miniaturized photodiodes in chip-scale package are probably the answer you’ve been looking for.

At Bee Photon, we specialize in exactly this – custom miniaturized photodiodes tailored for wearable sensors and health monitoring tech. We’ve helped teams just like yours get that extra edge.

Wanna chat about your specific project? Swing by our contact page or shoot us an email. We’d love to hear what you’re building!

Check us out at https://photo-detector.com/ or head straight to https://photo-detector.com/contact-us/ for a quick quote. Drop us a line at info@photo-detector.com – seriously, no pressure, just real talk about how we can help.

FAQ

Q: How small can photodiodes really get for smartwatches these days?

A: We’re seeing commercial options down to about 2 mm x 1.8 mm x 0.6 mm in chip-scale packages, with good sensitivity for PPG. Anything smaller often trades off performance, but tech keeps pushing.

Q: Do miniaturized photodiodes work well with different skin tones?

A: Better ones do – higher sensitivity and multi-wavelength support (green + red/IR) help a lot. We’ve seen accuracy stay solid across a wide range when the design is optimized.

Q: What’s the biggest benefit for AR/VR glasses specifically?

A: Space savings and low power. You can add ambient or proximity sensing without bulking up the frame or killing battery life, which is critical for all-day wear.