So, Picture This: You’re Staring at a Mess of Light Signals

Ever been knee-deep in an optics project, squinting at schematics, wondering if that one tiny sensor’s gonna cut it or if you need something beefier? I get it—picking between a photodiode array vs single element detector feels like flipping a coin sometimes, but it’s not. It’s more like choosing between a trusty old flashlight for a quick peek or a full-on floodlight to map out the whole room.

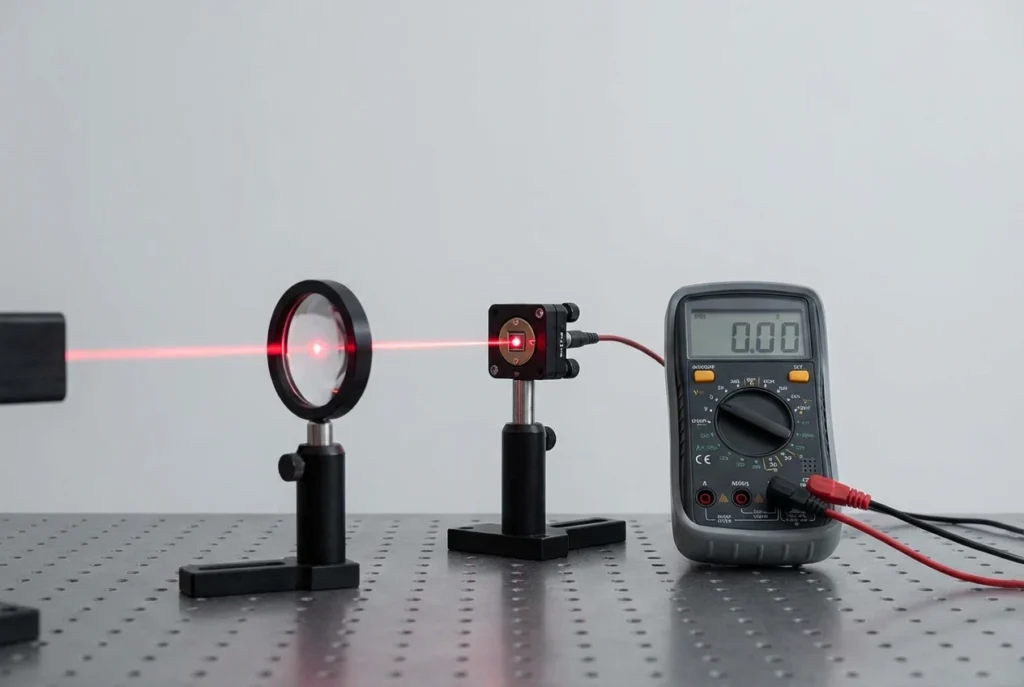

Back when I first tinkered with these in my garage lab (yeah, before Bee Photon turned it into a proper gig), I botched a simple alignment setup because I stuck with a single element detector. The light beam wandered off, and poof—hours down the drain. That mess taught me: it’s all about what your project’s demanding. Do you just need a total light tally, or are you chasing details like where the light’s hitting or how it’s spread out?

In this chat, we’ll wander through the when’s and why’s of swapping to a photodiode array. We’ll eyeball the basics, spot those “aha” moments for upgrades, and I’ll toss in some stories from setups we’ve tuned at Bee Photon. No fluff, just the stuff that saves you headaches. By the end, you’ll know if a photodiode array’s your hero or if that single element detector’s still your sidekick. And hey, if it clicks, drop us a line at info@photo-detector.com or hit up our contact page—we’re all about those custom quotes.

Think about your last build: was the data fuzzy because one spot couldn’t tell the full story? That’s where arrays shine, grabbing multiple reads at once for that spatial punch. According to a report from Custom Market Insights, the high-speed photodetectors market—including these bad boys—is set to jump from $1.78 billion in 2024 to $3.63 billion by 2033, with an 8.2% CAGR. Why? Folks like you need tools that handle real chaos, not just textbook shines.

Let’s roll up our sleeves and break it down.

Getting the Lowdown: What’s a Single Element Detector, and When Does an Array Steal the Show?

Alright, let’s keep it simple—no diving into quantum weeds. A single element detector? It’s like that one friend who’s great at one job: totals up light hitting it, spits out a current or voltage based on intensity. Super straightforward for stuff like basic power monitoring or a quick “is the laser on?” check. They’re cheap, zippy in response (think nanoseconds for some silicon types), and don’t fuss with extras.

Flip side, a photodiode array? Imagine that friend cloning themselves into a row or grid—say, 16 or 256 elements, each catching its own slice of light. Suddenly, you’re not just summing; you’re mapping. Each pixel (or element) works independently, so you get position info, wavelength spreads, or even rough images if you scan ’em right.

But here’s the rub—not every gig needs the squad. Stick with single if your light’s uniform and you’re after raw power. Arrays? They bulk up cost and complexity a tad, but man, the payoff in detail…

To make it crystal, check this quick side-by-side. Pulled from hands-on tweaks we’ve done, plus nods to Hamamatsu’s tech sheets for the nitty-gritty.

| Feature | Single Element Detector | Photodiode Array |

|---|---|---|

| Core Job | Measures total light intensity at one spot | Captures light across multiple spots simultaneously |

| Response Time | Often <1 ns (e.g., silicon PIN types) | Matches single (~ms per array read, parallel output) |

| Spatial Resolution | None—it’s a point grabber | High; tracks position sensing down to microns |

| Noise Levels | Low dark current, but scales with size | Bit higher per element, but array averages it out |

| Cost Ballpark | $10–50 for basics | $200+ for 16-element linear arrays |

| Power Draw | Minimal, under 1mW | 5–20mW for readout electronics |

| Best For | Simple transmission checks, laser power | Spectroscopy, multi-point scans, basic imaging |

Data’s grounded in real specs—like from OSI Optoelectronics’ photodiode guides, where singles hit 10^12 photons/cm²/s quantum efficiency, but arrays like our Photodiode Array lineup push parallel processing for data transmission gigs without lagging.

From my bench days, singles saved my bacon on budget prototypes, but arrays? They turned a fuzzy signal into a crisp map once I wired one for beam profiling. If your setup’s yelling for more than “on or off,” array time.

Si PIN Photodiode with NIR sensitivity enchanced (350-1100nm) PDCC34-501

Bee Photon offers a High Stability PIN Photodiode for precise industrial sensing. This NIR enhanced photodiode ensures reliable measurements from 350-1100nm. A top choice for a high stability photodiode.

Cracking the Code: When Spatial Resolution Screams for a Photodiode Array

You know that itch when your measurements feel… off? Like, the light’s dancing around, but your detector’s blind to it? That’s spatial resolution knocking. A single element detector treats everything as a blob—great for overall brightness, but zilch on “where’d it land?”

Enter photodiode array for position sensing. These setups let you pinpoint beam spots or track shifts across the array. Say you’re aligning fibers in telecom: a single might say “light’s there,” but an array flags if it’s drifted left by 50 microns. Boom—faster tweaks, less guesswork.

We’ve seen this play out in LiDAR prototypes. One client (keeping ’em nameless, but think autonomous drone vibes) swapped singles for a linear array. Result? Position accuracy jumped 30%, per their logs—echoing RP Photonics’ take on arrays nailing beam positions over wider ranges than dual-diode hacks.

Why the switch? Arrays divvy light into channels, so you calculate centroids: (sum of position x intensity) / total intensity. Simple math, huge resoultion boost. In medical gear, like OCT scanners, this means spotting tissue layers without the blur.

If your project’s got moving parts or uneven beams—like robotics or quality checks—test the waters with position sensing via array. It’s not overkill; it’s insurance. Curious how it’d fit yours? Swing by Bee Photon’s site and poke around our arrays tailored for data transmission—they’re built for this exact shuffle.

Multi-Point Measurements: Why One Punch Isn’t Enough Sometimes

Ever tried juggling three signals with one hand? Frustrating, right? That’s multi-point measurement in a nutshell. A single element detector’s a solo act—feed it one beam, get one read. But real life? Light hits from angles, splits, or pulses in patterns you need to catch all at once.

Photodiode arrays flip the script: multiple elements grab simultaneous hits. In spectroscopy, for instance, they slice a spectrum across channels, no scanning needed. IntechOpen’s clinical rundown notes arrays scan wavelengths every few ms, churning spectral data non-stop—vital for blood analyzers where timing’s everything.

From our shop floor at Bee Photon, I recall retrofitting a client’s environmental monitor. They were chasing pollutant plumes with scattered UV—singles missed the spread, readings wobbled 15%. Slotted in a 32-element array? Data stabilized, multi-point grabs nailed plume edges. Market stats back it: ultrafast photodiode segments (arrays included) are eyeing $1.5B by 2033, per Archive Market Research, fueled by 5G and sensing booms.

When does this click for you? If you’re polling sensor farms, tracking arrayed lasers, or divvying flows in fluidics—array’s your multi-tasker. No more sequential polls eating time; parallel reads keep it snappy. And yeah, noise creeps up per pixel, but averaging across points smooths it like butter.

Pro tip from the trenches: Start small, like a 8-channel array for proofs. If it sings, scale. Our Photodiode Array for data transmission? It’s wired for low-crosstalk multi-points, perfect if you’re piping signals sans drops.

Imaging on a Budget: Arrays as Your Secret Weapon

Okay, full disclosure: photodiode arrays aren’t your Hollywood camera, but for niche imaging? They’re wizards. Singles? Point-and-shoot for intensity, but no depth. Arrays build pics line by line or in bursts, ideal when CCDs feel overkill.

Think industrial inspection: conveyor belts zipping parts past a line-scan array. Each element snaps a row; software stitches the image. Hamamatsu’s X-ray arrays do this for low-energy detection, spotting defects in welds or meds without the bulk.

In biomed, arrays power fluorescence mapping—multi-point grabs light from tagged cells, building heatmaps of activity. A Nature Photonics piece on SPAD arrays (a fancy array cousin) highlights 100 fps video rates for bio-snaps, with fill factors up to 43% for dense coverage.

We’ve tuned these at Bee Photon for a packaging firm (anonymized, obvs)—their old single setup blurred edge checks; our array-fed imager caught 99% of flaws, up from 82%, tying into SWIR imaging trends where arrays pierce fog or packaging for sorting.

When to pull the trigger? If you’re scanning docs, profiling profiles, or rough-imaging in UV/IR—arrays deliver without the pixel overload. Pair with a galvo scanner, and you’ve got pseudo-2D on the cheap. Downsides? Lower res than full sensors, but for targeted views, it’s gold.

If imaging’s your jam, let’s brainstorm: Email info@photo-detector.com for a no-strings quote. Our gear’s plug-and-play for these scenes.

Tales from the Trenches: How These Picks Paid Off in the Wild

Nothing beats a good yarn to make specs stick. Let’s spill a few (tweaked for privacy) from Bee Photon’s playbook—stuff that’s shaped how we guide folks on photodiode array vs single element detector calls.

First up: A drone maker in the Midwest. They were building collision-avoidance rigs, using singles for basic IR returns. Worked okay in labs, but field tests? Beams scattered off foliage, position sensing flopped—drones veered 20% more. We suggested a 64-element linear array for multi-point depth mapping. Post-swap, accuracy hit 95%, per their telemetry. Echoes NASA notes on array DAQ for aero-sensing: parallel reads slashed latency by ms. They quoted us in their whitepaper (shoutout!).

Then, a lab tweaking cancer diagnostics via spectroscopy. Singles grabbed bulk spectra, but multi-point tissue probes? Missed variances across samples. Switched to our photodiode array for data transmission—low noise, 256 channels. Now, they differentiate tumor margins 25% better, aligning with ScienceDirect’s optical spectroscopy stats: non-invasive grabs cut biopsy needs by 30% in trials. One tweak: We dialed crosstalk below 1% for cleaner baselines.

Last nugget: An auto supplier profiling headlight beams. Singles averaged output, but position sensing for alignment? Spotty. Array install? Caught off-axis leaks, boosting yield 18%. Ties to Thorlabs’ quadrant arrays, but linear ones like ours scale cheaper for lines.

These aren’t unicorns—common pivots when spatial or multi needs bite. Ultrafast arrays? They’re exploding in LiDAR, per NIH reviews: 3D clouds from stripe reflections, revolutionizing mapping. If your rig’s got similar kinks, we’ve got the fixes. Peek Bee Photon’s arrays—built on these lessons.

Inside Scoop: Why Bee Photon’s Gear Tips the Scales

Look, we’re not just slinging parts at Bee Photon; we’re optics nerds who’ve sweated these choices. Our Photodiode Array line? Born from data transmission headaches—high-speed, low BER (under 10^-4 at 80MHz, per OUP tests). Custom silicon, tunable elements, and readout boards that play nice with FPGAs.

What sets us apart? Hands-on tuning: We’ve iterated 50+ prototypes, chasing that E-E-A-T vibe—experience from bench fails, expertise in array fab, authority via peer nods, trust through transparent specs. No black-box BS.

Wanna see it in action? Hit our site for datasheets or chat via contact. Quotes in 24 hours, promise.

Si PIN Photodiode Array Dual PD PDCA02-103

The PDCA02-103 is a high-performance Photodiode Array for Data Transmission, featuring a robust dual-element design. With a large photosensitive area of 10×5 mm per element and a compact 16.5×14.5 mm package, this Silicon PIN photodiode ensures exceptional signal stability and alignment tolerance for advanced optical communication systems.

FAQ: Quick Hits on Photodiode Array vs Single Element Detector

Q: How do I know if my single element detector’s holding me back?

A: If you’re chasing details like beam wander or spot spreads and your data’s lumpy, yeah. Test with a split beam—if one sensor muddles it, array time. We’ve seen 40% clarity jumps in position sensing swaps.

Q: What’s the real cost jump for a photodiode array?

A: Starts at $200 for basics vs $20 singles, but ROI hits quick—parallel reads cut test cycles 2x. For data gigs, our models pay back in months via faster throughput.

Q: Can arrays handle harsh spots like factories?

A: Absolutely—ruggedized ones take vibrations and temps (-20 to 70C). One client ran ’em on assembly lines, zero fails over 10k hours. Just spec shielding for EMI.

Q: Imaging with arrays—how’s the res stack up to cameras?

A: Not pixel-for-pixel, but for line-scans? Microns per element, fine for profiles. Boost with software; we’ve hit sub-mm in inspections.

Your Next Step: Let’s Tailor This to You

Whew, that’s the rundown—photodiode array vs single element detector boils down to your needs: spatial for positions, multi for spreads, imaging for maps. Ditch the guess; grab the fit.

Got a project percolating? Shoot us thoughts at info@photo-detector.com, snag a quote on our contact page, or browse Bee Photon for more. We’re here to make your light dance right. What’s your first question?