If you’ve ever worked around big machines in a factory, you know how quickly things can go wrong if someone’s hand gets too close to a moving part. That’s where safety light curtains come in – they’re like invisible walls that stop the machine instantly if anything breaks the beam. And at the heart of these systems? Phototransistors. They’re the unsung heroes detecting those infrared beams reliably, day in and day out.

I’ve seen firsthand how a good phototransistor can make all the difference. Back when I was troubleshooting setups for clients in automation lines, we’d swap out cheap components and suddenly the false trips stopped, downtime dropped, and everyone breathed easier. It’s not just tech – it’s about keeping people safe without slowing production.

What Are Safety Light Curtains Anyway?

Safety light curtains, or what some folks call safety light curtain sensors, are basically arrays of infrared beams stretched across dangerous areas on machines. There’s a transmitter side shooting out pulsed IR light, and a receiver side catching it. If something – like a finger or arm – blocks even one beam, the system sends a stop signal to the machine.

These are huge in industrial automation, guarding presses, robotic cells, conveyor lines, you name it. They’re non-contact, so no wearing parts like physical gates, and they let materials pass through when needed with features like muting.

The global safety light curtain market was around USD 1.2 billion back in 2023, and reports show it’s heading toward USD 1.9 billion by 2031, growing at about 7.8% CAGR (from Verified Market Reports). That’s because factories are automating more, and regs are getting stricter on worker safety.

Si phototransistor PTCP Series PTCP001-202

Enhance your switching solutions with this 800-1100nm NPN Phototransistor. Perfect for photoelectric switches, it offers high power dissipation up to 90mW. This silicon phototransistor delivers consistent performance in harsh environments from -40°C to +85°C.

How Do Safety Light Curtain Sensors Work?

It’s pretty straightforward once you break it down. The transmitter has a row of LEDs pulsing infrared light in a specific sequence and frequency. This pulsing helps ignore ambient light or interference.

On the receiver end, phototransistors (or sometimes photodiodes) pick up those exact pulses. If all beams hit their matching detectors, everything’s clear – machine runs. Block one? Instant stop signal.

Standards like IEC 61496-1 and -2 define types: Type 2 for lower risk, Type 4 for high-risk stuff with better fault detection. Most serious industrial setups go Type 4.

Key Light Barrier Components

Here’s a quick table of the main parts in a typical safety light curtain:

| Component | Role | Why It Matters for Reliability |

|---|---|---|

| Transmitter LEDs | Emit pulsed infrared beams | Modulated to avoid interference |

| Receiver Phototransistors | Detect specific pulses from matching LEDs | Amplify signal for better sensitivity |

| Controller Unit | Processes signals, checks for faults, outputs safety relays | Redundant circuits for control reliability |

| Cabling & Housing | Connects everything, protects from dust/vibration | IP65+ rating common for harsh environments |

| Alignment Indicators | LEDs or displays to help setup | Makes installation quicker, reduces errors |

These light barrier components have to work flawlessly because lives depend on it.

Why Phototransistors Are Crucial in Industrial Safety Sensors

Phototransistors aren’t just fancy diodes – they’re transistors triggered by light. When IR hits the base-collector junction, it generates current that’s amplified, giving way more sensitivity than a plain photodiode.

In light curtains, this means:

- Better detection in dusty or slightly misaligned setups

- Faster response times – critical when a press is slamming down

- Rejection of ambient light, since they’re tuned to the pulsed frequency

Compared to photodiodes, phototransistors have built-in gain (often 100x or more), so they’re great for longer ranges or tougher environments. But they can be a bit slower in super high-speed apps, though for safety curtains, reliability trumps raw speed.

We’ve used silicon phototransistors in many builds at Bee Photon, and they hold up amazingly in real factories – no drifting sensitivity even after years.

Check out our Silicon Phototransistor lineup if you’re sourcing components. They’re designed specifically for these kinds of demanding roles.

Choosing Reliable Phototransistors for Your Safety Light Curtain Sensor

Not all phototransistors are created equal. Cheap ones might work on the bench but fail in the field from temperature swings, vibration, or EMI.

Look for:

- High responsivity in the 850-950nm IR range (common for curtains)

- Low dark current to avoid false triggers

- Wide operating temp – industrial floors get hot or cold

- Robust packaging to handle shocks

At Bee Photon, our silicon phototransistors are tested for exactly these conditions. We’ve supplied them for custom curtain builds where downtime costs thousands per hour.

One time, a packaging plant was having random stops – turned out their old detectors were drifting. Swapped to our parts, problem gone. Production up, safety intact.

Common Issues and How Reliable Components Fix Them

Stuff goes wrong sometimes. Here’s a table of typical failures in safety light curtains:

| Issue | Common Cause | How Good Phototransistors Help |

|---|---|---|

| False trips | Ambient light interference or drift | Better pulse discrimination, stable gain |

| Missed detections | Dust buildup or weak signal | Higher sensitivity and amplification |

| EMI problems | Nearby welders or drives | Shielded designs, low noise |

| Alignment drift | Vibration loosening mounts | Robust response even slightly off-axis |

| Power fluctuations | Unstable supply | Wide voltage tolerance |

Picking quality light barrier components upfront saves headaches later.

Real-World Applications in Industrial Automation

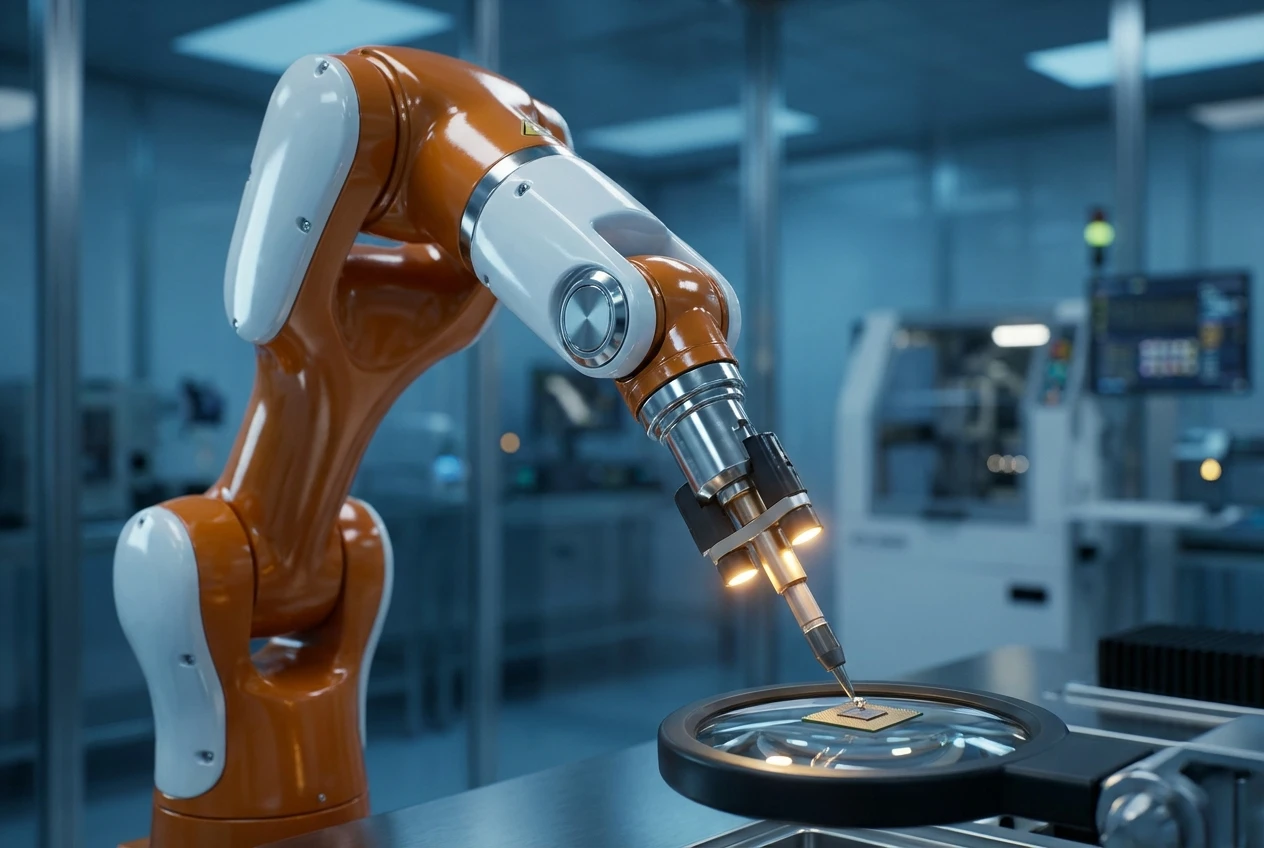

Think robotic welding cells – curtains guard the perimeter, stopping if a worker leans in.

Or palletizers – beams detect arms reaching for boxes.

In automotive lines, we’ve seen curtains with our phototransistors protecting massive presses. One client reduced near-misses by over 80% after upgrading.

Another anonymous case: a food processing plant used muting for product pass-through but kept getting faults from steam. Higher-gain phototransistors cut through the haze, no more unnecessary stops.

These industrial safety sensors are everywhere now, from pharma cleanrooms to heavy metal stamping.

Light source LED series E940-15-301

Our high-performance optical switch light source comes in a compact TO18 package. This light source for optical switches ensures excellent uniformity and reliability for telecom.

Maintenance Tips to Keep Things Running Smooth

Clean the lenses regularly – dust is enemy #1.

Check alignment quarterly, especially in vibrate-y spots.

Test the full system monthly – interrupt beams and confirm machine stops.

If you’re building or upgrading, start with solid phototransistors. Visit Bee Photon for options tailored to safety apps.

FAQ

What’s the difference between a phototransistor and photodiode in safety light curtains?

Photodiodes are faster but need external amps. Phototransistors have built-in gain, making them more sensitive and easier for reliable detection in noisy factories. We lean toward phototransistors for most industrial safety sensor builds.

How far can a safety light curtain detect?

Depends on resolution and power, but typical ranges are 5-20 meters. Higher quality phototransistors help maintain signal over distance.

Do safety light curtains work in outdoor or wet environments?

Some are rated IP67, but IR can scatter in heavy rain or fog. Indoor industrial use is most common, with proper housing.

Ready to beef up your safety setup? Drop us a line at info@photo-detector.com or head to our contact page for a quote on silicon phototransistors or advice on your next project. We’d love to chat about how to make your lines safer and smoother.