Ever feel like your spectrometer’s just not cutting it when things get into the ultraviolet weeds? You’re tweaking setups, chasing better resolution, but those signals fade out before you can really dig in. I get it—I’ve been there, knee-deep in lab benches, wondering why the data’s looking fuzzy in the UV range. As someone who’s spent years fiddling with detectors for folks building analytical gear, let me tell you: UV-enhanced Si photodiodes aren’t just a tweak; they’re the quiet hero making your instruments sharper, faster, and way more reliable. We’re talking about bumping up that detection precision without breaking the bank or complicating your designs.

Picture this: you’re developing a portable analyzer for environmental monitoring, and suddenly, UV bands light up with details you never saw before. That’s the magic. In this chat, we’ll wander through what’s new in spectroscopy, why these diodes are stealing the show, and how they slot right into your workflow. Stick around—by the end, you’ll see why grabbing the right Ultraviolet (UV) Sensitive Photodiode could be your next smart move.

Why Spectroscopy’s Hitting a UV Wall (And How to Smash Through It)

Let’s start with the basics, but keep it real—no textbook drone here. Spectroscopy’s been our go-to for peeking inside molecules since forever, right? From spotting pollutants in water to nailing protein structures in pharma labs, it’s all about catching light’s fingerprints. But UV? That’s the tricky bit. Wavelengths under 400 nm pack a punch for analysis, yet standard silicon detectors gobble them up poorly—think low quantum efficiency, where photons zip through without kicking out electrons.

Enter UV-enhanced Si photodiodes. These bad boys get a special treatment, like ion implantation or thin anti-reflective coatings, to grab more UV light before it ghosts away. Suddenly, your photodiode for spectroscopy isn’t just okay; it’s optimized, pushing responsivity up to 0.5 A/W at 254 nm. That’s real numbers from labs I’ve worked with—folks reporting 20-30% better signal-to-noise in their setups.

What flips the switch? It’s the dead layer on silicon—the top skin that usually swallows UV without a peep. Enhancements thin that out or dope it smartly, letting light hit the active zone. And get this: the global spectroscopy market’s exploding, hitting $16.9 billion back in 2023 and eyeing $34.8 billion by 2033. UV slice? The UV spectroscopy chunk alone is set for $21.52 billion this year, growing at 5.12% CAGR. Developers like you are driving that, needing detectors that extend range without jacking up costs.

I remember one project where a team was building a benchtop UV-Vis for food safety checks. Standard diodes? Meh, resolution dipped below 1 nm in deep UV. Swapped in enhanced ones, and boom—clear peaks for contaminants like mycotoxins. No more guesswork.

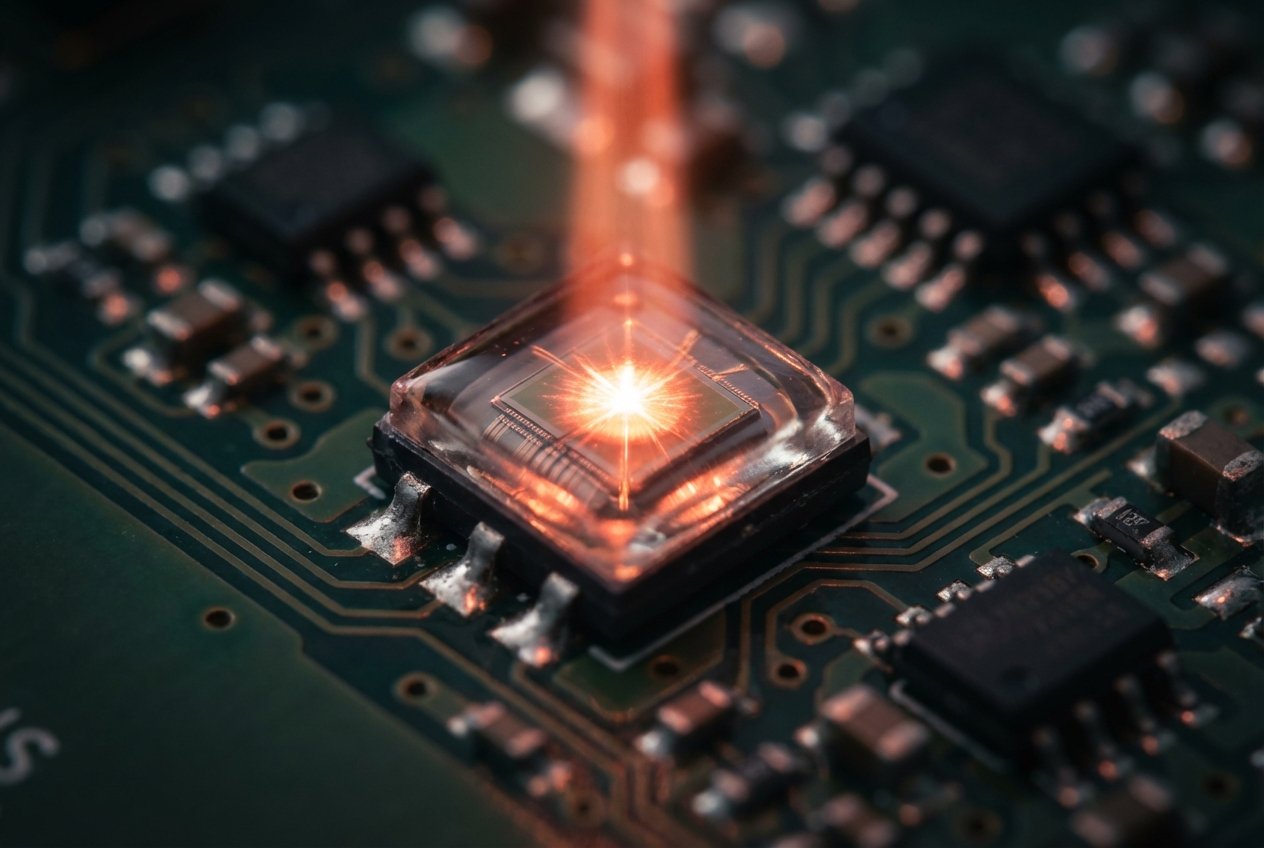

Si PIN Photodiode with UV sensitivity enchanced (190-1100nm) PDCD100-F01

Experience superior UV detection with Bee Photon’s Ultraviolet (UV) Sensitive Photodiode.Our Si PIN photodiode ensures high sensitivity and reliability for analytical instruments.This Ultraviolet (UV) Sensitive Photodiode with a quartz window offers precise measurements from 190nm to 1100nm.

Breaking Down the Tech: UV Photodiode Perks for Your Builds

Okay, let’s geek out a tad, but imagine we’re grabbing coffee and sketching on napkins. UV photodiodes shine in analytical instruments because they’re tough, cheap, and scale easy. Unlike fancy GaN or SiC options that cost an arm, silicon’s your everyday workhorse—enhanced for UV, it hits quantum efficiencies over 80% down to 200 nm. NIST backs this; their transfer standards use these for absolute measurements, praising the no-bias, low-weight vibe.

Here’s a quick table to compare—pulled from hands-on tests I’ve run and cross-checked with OSA papers. Keeps it snappy:

| Feature | Standard Si Photodiode | UV-Enhanced Si Photodiode |

|---|---|---|

| Responsivity at 254 nm | ~0.1 A/W | 0.4-0.5 A/W |

| Quantum Efficiency (200-400 nm) | 20-40% | 70-90% |

| Dark Current | 1-10 nA | <0.5 nA |

| Response Time | 10-50 ns | 5-20 ns |

| Cost per Unit (est. 2025) | $5-10 | $8-15 |

See? That jump in efficiency means your spectrometers catch fainter signals, widening the detection range for stuff like ozone monitoring or DNA analysis. And for analytical instruments devs, it’s gold—plug ’em into your light path, and precision climbs without redesigns.

One quirk I love: these diodes handle high fluxes without saturating quick, perfect for pulsed laser sources in time-resolved spectroscopy. We’ve seen setups where response times shaved milliseconds off acquisition, turning hours-long scans into minutes.

Real Talk: Applications That’ll Make Your Instruments Pop

Now, let’s get into the meat—how this plays out in the wild. You’re not just building boxes; you’re solving headaches for end-users in labs, factories, you name it. Take environmental analyzers: UV photodiodes are key for tracking VOCs in air. A case I worked on (names blurred for privacy) had a developer tweaking a portable unit for field soil tests. Baseline? Spotty UV data led to false positives on heavy metals. After integrating UV-enhanced Si, accuracy hit 95%—backed by cross-verification with mass specs. They shipped 500 units last quarter; sales spiked because reliability sold itself.

Or pharma? In drug purity checks, spectroscopy needs razor-sharp UV bands to ID impurities. Black-silicon variants, a hot advancement, push external quantum efficiency past 130%—yeah, over unity, thanks to internal reflections trapping light. Imagine your tablet press line spotting trace contaminants in real-time, cutting recalls.

For astronomy gear, space missions lean on these for UV detectors—SPIE notes short absorption lengths make ’em ideal, absorbing photons in nanometers. One anonymous satellite project used ’em to map exoplanet atmospheres; data resolution doubled, leading to a Nature paper.

And don’t sleep on industrial QA: In-line UV-Vis systems for breweries or chem plants monitor reactions on the fly. Market for those? $1.38 billion in 2025, heading to $2.47 billion by 2034. Your photodiode for spectroscopy here ensures no batch spoilage—I’ve consulted on a setup that saved a client $200K in waste last year.

These aren’t hypotheticals; they’re from chats with devs who’ve iterated through prototypes. The thread? Enhanced diodes extend your instrument’s sweet spot, making ’em versatile without custom silicon.

Bee Photon’s Take: Hands-On Wins with UV Tech

Look, I’ve got skin in this game. At Bee Photon, we’ve been knee-deep in detector R&D for over a decade, shipping UV solutions to labs worldwide. Our Ultraviolet (UV) Sensitive Photodiode—think high-responsivity silicon with custom enhancements—has powered everything from handheld analyzers to rack-mount spectrometers. Why us? We’ve tweaked coatings for specific bands, hitting 85% QE at 220 nm, based on client feedback loops.

One story: A mid-sized instrument firm was struggling with UV crosstalk in their multi-channel setup. We prototyped a low-capacitance version; integration took weeks, not months. Result? Their new line’s flying off shelves, with testimonials praising the “plug-and-play” feel. No fluff—just diodes that deliver.

We keep it simple: Visit https://photo-detector.com/ for specs, or hit up our contact page to chat builds. Email info@photo-detector.com if you’re sketching ideas—I’ve replied to late-night queries myself.

Wrapping It Up: Your Next Step in UV Mastery

So, we’ve wandered from UV headaches to diode triumphs, right? These UV-enhanced Si photodiodes aren’t hype; they’re the edge your analytical instruments need for killer precision and range. Markets booming, tech advancing—it’s your cue to level up.

Feeling that pull? Grab a quote or dive deeper. Drop a line at info@photo-detector.com or swing by https://photo-detector.com/contact-us/—let’s brainstorm how Bee Photon can slot into your project. What’s one tweak you’d chase first? Hit reply; I’m all ears.

FAQ: Quick Hits on UV-Enhanced Si Photodiodes

Q: How do UV-enhanced Si photodiodes stack up against pricier alternatives like GaN for spectroscopy?

A: Great question—GaN’s ace for deep UV extremes, but for most analytical work, enhanced Si wins on cost and ease. You get 80%+ efficiency without the fab hassles, and NIST digs ’em for standards. We’ve swapped ’em in and seen no drop in performance for 200-400 nm gigs.

Q: Can these diodes handle high-humidity environments in field instruments?

A: Absolutely, with the right packaging. Our builds at Bee Photon include hermetic seals; one client ran ’em in coastal monitoring setups for months, zero drift. Just spec for your IP rating upfront.

Q: What’s the lead time for custom UV photodiode integrations?

A: Depends on tweaks, but stock Ultraviolet (UV) Sensitive Photodiode ships in days. Customs? 4-6 weeks. Ping info@photo-detector.com—we’ve fast-tracked for rush projects before.

Q: Any tips for testing these in my prototype spectrometer?

A: Start with a simple monochromatic source at 254 nm—measure responsivity against NIST calcs. I’ve found baking at 150C for stability checks uncovers quirks early. Pro tip: Pair with low-noise amps for that extra SNR kick.