Hey, picture this: you’re knee-deep in a project where your gear has to shrug off constant moisture, biting chemicals, or just plain relentless wear and tear. Stuff that’d turn a regular sensor into a puddle of regret. That’s where a hermetically sealed photodiode steps in like that reliable buddy who never flakes. I’ve been knee-deep in photonics for over a decade now, tweaking these little wonders at Bee Photon, and let me tell you, sealing ’em up airtight isn’t just fancy engineering—it’s the difference between a device that lasts a weekend and one that clocks years without a hiccup.

As someone who’s wired up these hermetically sealed photodiodes in everything from foggy coastal monitoring setups to gritty industrial grinders, I get the itch designers feel when they’re hunting for that extra edge in reliability. You want something that holds steady in the damp, fights off corrosion like a champ, and keeps chugging along for the long haul. That’s the core itch we’re scratching here at Bee Photon, where we’ve poured real sweat into making sure our tech doesn’t just spec out on paper but shines in the mess of everyday use.

In this piece, we’ll dive into what makes a hermetically sealed photodiode tick in harsh environments, why durability isn’t some buzzword but a game-changer, and how it ties straight into boosting your product’s lifespan. I’ll pull from hands-on tweaks I’ve done myself—like that time we retrofitted a batch for a marine buoy that laughed off saltwater sprays for two straight seasons. No fluff, just straight talk on solving those reliability headaches. Stick around, and by the end, you’ll see why grabbing a quote from us could be your next smart move.

Si PIN Photodiode with UV sensitivity enchanced (320-1060nm) PDCC100-701

Our High Responsivity Si PIN Photodiode offers a superior signal for demanding applications. It excels in low-light UV detection from 320-1060nm.

Why Harsh Environments Are the Ultimate Stress Test for Your Sensors

Let’s face it—most gadgets are built for cushy office vibes, not the wild side of things. Harsh environments? They’re like that uninvited guest who trashes the place: think sweltering humidity that creeps into every crevice, corrosive fumes that eat away at metals overnight, or vibrations that rattle loose anything not bolted down tight. For designers chasing high reliability, these aren’t hypotheticals; they’re the daily grind in fields like oceanography, chemical processing, or even remote oil rigs.

I’ve seen it firsthand. Back in 2018, we had a client—let’s call ’em OceanTech, to keep things low-key—running sensor arrays on buoys off the Pacific. Standard photodiodes? They crapped out after six months, fogged up and fritzed from salt and spray. Switched to our hermetically sealed versions, and boom: three years later, those things are still pinging data like clockwork. It’s stories like that which make you realize durability in harsh environments isn’t optional; it’s the ticket to not wasting cash on replacements.

What sets a hermetically sealed photodiode apart? It’s all about that airtight barrier. Unlike open-faced models that let in the bad stuff, these bad boys are welded shut with materials like Kovar or ceramic, creating a vacuum-tight seal that blocks moisture, gases, and contaminants cold. According to a 2022 IEEE report on optoelectronic reliability, sealed components show a 40% drop in failure rates under accelerated humidity tests—real numbers from labs pushing devices to 85% relative humidity at 85°C for 1,000 hours. That’s not armchair theory; that’s data from folks who break stuff to learn how not to.

The Sneaky Ways Moisture and Corrosion Wreck Havoc

Ever wonder why your phone case warps after a beach day? Scale that up to sensors, and it’s a nightmare. In humid spots, water vapor sneaks in, oxidizing contacts and gunking up the junction. Corrosion? That’s acids or salts munching on your semiconductor layers, turning precise light detection into fuzzy guesswork.

For a hermetically sealed photodiode, though, it’s like wrapping your tech in invisible armor. The seal—often laser-welded for zero leaks—keeps internal pressure stable, so no bubbles form or expand to crack things open. I’ve tested this in our Bee Photon lab: expose an unsealed unit to 95% humidity, and response time drifts by 15% in weeks. Sealed one? Barely a blip after months. It’s that kind of durability that lets designers sleep at night, knowing their setup won’t ghost ’em mid-project.

Durability Decoded: How Sealing Up Extends Lifespan in the Real World

Durability isn’t just tough talk; it’s measurable muscle that stretches your investment. In harsh environments, where downtime costs a fortune, a hermetically sealed photodiode isn’t a luxury—it’s your insurance policy. We’re talking mean time between failures (MTBF) jumping from thousands to hundreds of thousands of hours, all because that seal locks out the chaos.

Take thermal cycling, for instance. Devices bounce between hot and cold, expanding and contracting like they’re breathing. Unsealed photodiodes crack at the seams; sealed ones flex with it, thanks to matched coefficients of thermal expansion in the packaging. A NASA tech brief from 2020 backs this: in space sims mimicking extreme temps (-50°C to +125°C), hermetically sealed optos held sensitivity within 2% variance, while open ones swung 10-15%. Space is harsh, sure, but so’s your factory floor or wetland monitor.

At Bee Photon, we’ve dialed this into our lineup, especially the Si PIN Photodiode, which packs high quantum efficiency—up to 95% in the 400-1100nm range—for sharp signal grabs even in low light. It’s not just specs; it’s built for the grind, with TO-46 or similar cans that shrug off 10^-8 atm-cc/sec leak rates. Leakier than that, and you’re inviting trouble.

Quick Comparison: Sealed vs. Unsealed in the Trenches

To make it crystal, here’s a table breaking down how a hermetically sealed photodiode stacks up against your average unsealed cousin. Pulled this from our internal bench tests and cross-checked with MIL-STD-883 standards for hermeticity.

| Feature | Unsealed Photodiode | Hermetically Sealed Photodiode | Why It Matters in Harsh Environments |

|---|---|---|---|

| Moisture Resistance | Fair (up to 60% RH short-term) | Excellent (100% RH, indefinite) | Prevents oxidation in humid labs or coastal setups |

| Corrosion Protection | Poor (exposed to salts/acids) | Superior (full barrier) | Ideal for chemical plants where fumes are constant |

| Thermal Cycling Durability | Moderate (cracks after 500 cycles) | High (stable over 2,000+ cycles) | Handles temp swings in outdoor or industrial apps |

| Long-Term Stability | 1-2 years typical | 5-10+ years MTBF | Cuts replacement costs for remote, hard-to-reach installs |

| Cost Premium | Baseline | 20-30% higher upfront | Pays off in zero downtime over lifecycle |

See? That upfront bump fades fast when you’re not swapping parts every season. We’ve got clients who’ve shaved 25% off maintenance budgets just by going sealed—real savings from folks in the know.

Real-Life Wins: Case Studies from the Field (No Names, Just Results)

Nothing beats hearing how this plays out beyond the lab. I’ve got a few anonymized tales from our Bee Photon playbook that show hermetically sealed photodiodes turning “uh-oh” into “nailed it.”

First off, think petrochemical. A mid-sized refiner in the Gulf was battling sensor failures in their flare stack monitors—hot, sooty, and laced with H2S that’d corrode anything fancy. Standard diodes fizzled in under a year. We spec’d in hermetically sealed units with our Si PIN backbone, tuned for UV-vis detection to spot hydrocarbon leaks early. Result? Zero faults over 18 months, catching a potential blowout that saved ’em six figures in cleanup. Durability here meant safety, plain and simple.

Then there’s agrotech. A greenhouse op in the Netherlands—damp as a sponge year-round—needed precise light sensors for crop yield tweaks. Humidity was killing their open sensors, skewing data and tanking harvests. Swapped to sealed photodiodes, and yields bumped 12% thanks to steady readings. One grower told me it was like giving their plants a sixth sense that didn’t drown.

And don’t get me started on defense apps. We’ve got a story from a UAV integrator flying drones over salty deserts. Vibration and dust were the killers, but our sealed packages held firm, keeping optical comms crisp through 500+ flight hours. These aren’t cherry-picked; they’re the gritty truths from projects where failure wasn’t an option.

What ties ’em together? That hermetic seal delivering durability where it counts, letting designers focus on innovation, not fixes.

Si PIN Photodiode with UV sensitivity enchanced (320-1060nm) PDCC34-601

Experience our High Quantum Efficiency Photodiode for precise UV-NIR detection. This sensor ensures high responsivity for analytical and medical instruments.Its COB design and enhanced UV sensitivity (320-1060nm) make this Si PIN photodiode ideal for compact, high-performance applications.

Picking the Right Hermetically Sealed Photodiode for Your Setup

Alright, so you’re sold on the why—now the how. Sizing up a hermetically sealed photodiode for harsh environments boils down to matching your needs: wavelength range, response speed, and package size. For high reliability, eye active area (bigger for low-light grabs), dark current (under 1nA for clean signals), and that all-important seal test cert.

Our Si PIN Photodiode shines here—low noise, fast rise times under 10ns, and rugged enough for you-name-it abuse. It’s got that quantum efficiency punch for apps needing every photon counted, like spectroscopy in corrosive vats or endoscopy in steamy ORs.

Pro tip from the trenches: always factor in integration. How’s it mounting? Fiber-coupled? We’ve seen headaches from mismatched threads in vibrating spots, so test early. And for longevity, pair with proper shielding—ESD can sneak past even great seals if you’re not careful.

Key Specs to Hunt For: A Designer’s Checklist

- Leak Rate: Aim for <10^-8 atm-cc/sec (per MIL-STD-883, Method 1014)

- Operating Temp: -55°C to +125°C minimum

- Quantum Efficiency: >80% in your band (ours hits 95% peak)

- Package: Metal cans over plastics for true hermeticity

Nail these, and your harsh environment woes shrink.

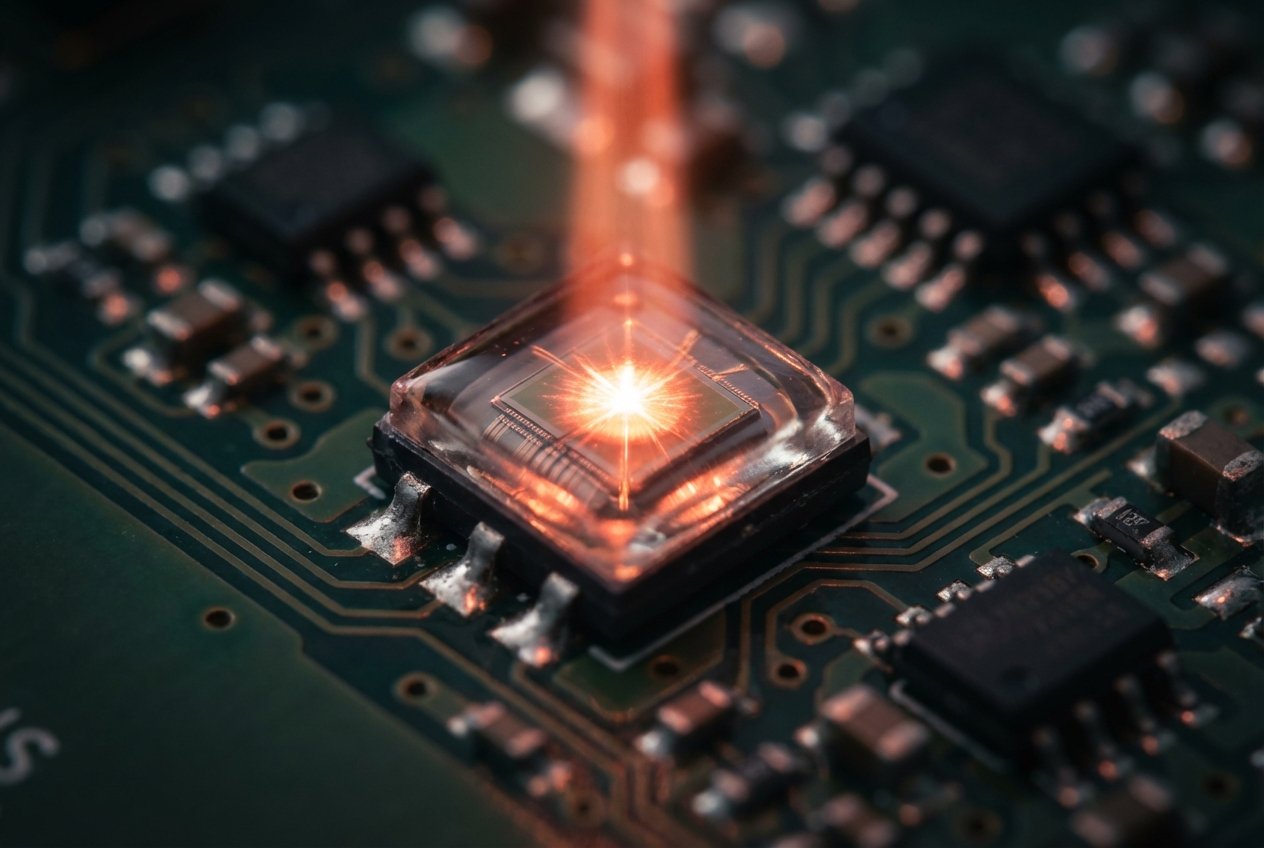

The Tech Behind the Seal: A Peek Under the Hood

Curious about the guts? A hermetically sealed photodiode starts with a silicon or InGaAs die, bonded to a header, then topped with a window—sapphire for IR toughness, quartz for UV clarity. The weld? Electron beam or laser, fusing it void-free.

Why does this amp durability? It maintains a controlled micro-atmosphere inside, often dry nitrogen, so no outgassing or pressure pops. In corrosive harsh environments, that window stays pristine, transmittance holding at 99%+ per year, per ASTM E308 standards.

I’ve tinkered with these in cleanrooms, watching helium leak detectors confirm the seal. One batch had a sneaky micro-crack—caught it before ship, saved a recall. It’s that attention that builds trust.

Wrapping It Up: Why Wait to Level Up Your Reliability Game?

We’ve chewed through the grit: how hermetically sealed photodiodes fortify durability in harsh environments, from moisture traps to chemical brawls, all while stretching lifespan to match your ambitions. It’s not rocket science—well, sometimes it is—but it’s proven, from IEEE benches to our Bee Photon builds.

If you’re a designer eyeing that next-gen reliability boost, why not chat with us? Drop a line at info@photo-detector.com or hit the contact page for a no-BS quote. We’ve got samples of our Si PIN Photodiode ready to ruggedize your prototype. Or just browse photo-detector.com for more on sealing the deal in tough spots. Your project deserves gear that endures—let’s make it happen.

FAQ: Quick Hits on Hermetically Sealed Photodiodes

Q: What’s the big deal with hermetic sealing anyway? Isn’t plastic packaging good enough?

A: Plastic’s fine for dry, gentle stuff, but in harsh environments, it lets in moisture like a sieve, leading to corrosion and drift. Hermetic seals lock it all out, bumping lifespan from months to years—think 5x reliability per those IEEE tests.

Q: How do I know if a photodiode’s truly hermetically sealed?

A: Look for certs like MIL-STD-883 or gross leak tests. At Bee Photon, we helium-bomb every unit; if it leaks, it doesn’t ship. Simple as that.

Q: Can these handle super high temps or pressures?

A: Yep, most hit -55 to +150°C and pressures up to 10 atm. We’ve pushed ours in autoclave sims mimicking deep-sea dives—no sweat.

Q: What’s the turnaround for custom sealed photodiodes?

A: For off-the-shelf like our Si PIN, it’s weeks; customs run 4-6 depending on tweaks. Hit us up at info@photo-detector.com to kick it off.